The roots of H. Krieghoff lie in Suhl, Thuringia, the former center of hunting and sporting gun manufacturing in Germany. It was here that the young Berthold Selmar Ludwig Krieghoff, who came from Nordhausen, moved in the 1880s. He worked as a teacher, but lost this job when, on the occasion of a bet for the then immense sum of 100 gold marks, he drove a sow around the village marketplace in his underpants. This story is vouched for, but brought him great trouble afterwards. Nevertheless, it turned out to be a stroke of luck for him, because shortly afterwards he got a job in Suhl and married the daughter of the local school principal, who took a liking to the young, energetic man.

The teaching profession did not pay much, so in 1886 Krieghoff and his American partner Sempert founded the firm "Sempert & Krieghoff". The company was a modest three-man workshop in the early days, like many of Suhl "hunting gun factories" of the time. In addition to small gun parts, they also built accessories for electrical systems, the field of knowledge of factory owner Sempert, who, according to legend, learned directly from Thomas Edison. Things went well for a while, then the "Great Depression" also reached Suhl, Sempert emigrated to the USA again and Krieghoff closed the electrical division forever, for which he never had an affinity.

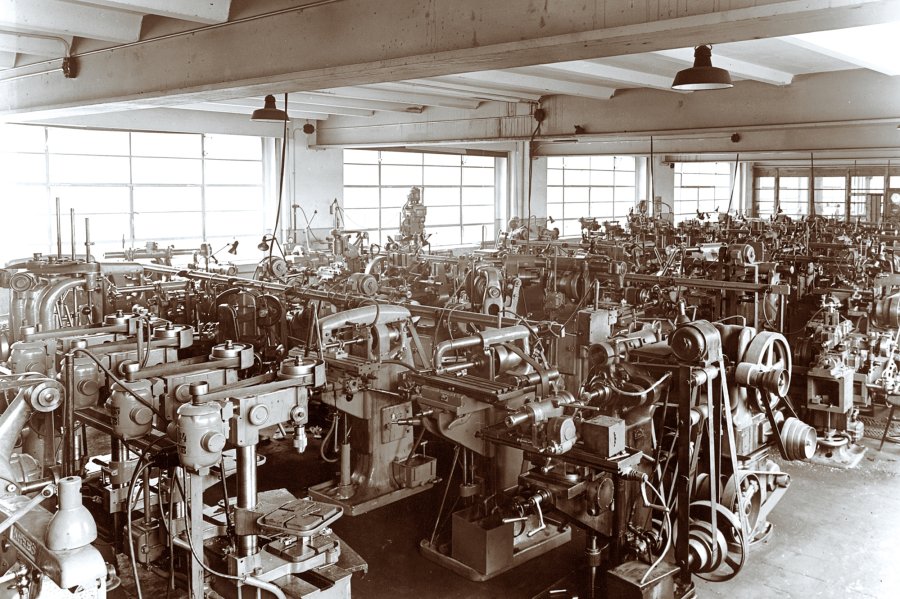

Turbulent founding years of Krieghoff GmbH around 1900

Turbulent years followed: among other things, Krieghoff had to answer to the jury court in 1899. At that time, the mailboxes of Krieghoff and Sauer & Sohn were next to each other. Orders for Sauer & Sohn were wrongly placed with Krieghoff, which he unjustifiably had executed. Of course, the matter was discovered, but Krieghoff was able to prove an oversight and not a deliberate criminal act in court, so that he remained unpunished.

The company grew steadily and experienced a great upswing when the younger son Heinrich, after completing his apprenticeship with the gunsmith Funk, the engraver Heim as well as the barrel maker Klett and numerous internships abroad, founded his own company, the "Heinrich Krieghoff Waffenfabrik", in 1916. In 1919, he also took over his father's business, which continued to exist in parallel (organizationally and fiscally) for decades and was only gradually integrated. Prior to this, he had seen the advantages of industrial firearms production in Liège, Belgium, Sheffield, England, and Birmingham, and introduced this know-how to his own company.

During the First World War full employment prevailed in Suhl, with shifts lasting twelve hours and more, and some work also being done at night. Krieghoff produced many supplier parts here – mainly springs – for other gun manufacturers, important action parts for the 98 rifle and around 10,000 complete Walther Model 4 pistols, some of which also bear the Krieghoff stamp. The 1920s and 1930s were golden times for the company in terms of technical advancements and sales figures. In 1925, the company produced its ten thousandth hunting gun, which was celebrated extensively. The company was also represented in Africa with large-caliber bolt-action rifles for the powerful 12.5x72 Schüler cartridge.

Patented designs: innovations from the Krieghoff firm

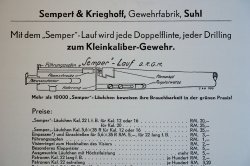

During these decades, some patents that had already existed for some time were further improved, built and sold. For example, the Precision Safety, a firing pin safety that, according to the description, "is intended to protect against all possibilities of unintentional discharge of the gun, regardless of the hunter's will": a technical improvement in which a spring-loaded lever connected to and movable with the trigger blade automatically secures the firing pin until the trigger is pulled. Also famous is the patented butt cap (now called the recoil pad) that can be changed without tools. This allows you to use a shorter one for winter and a longer one for summer, and the stock length is always the same regardless of clothing. Until the end of the Second World War, these pads were manufactured in Suhl, then they fell into oblivion. Currently Wegu supplies similar models. A very popular classic in West Germany until the 1970s was the Semper insert barrel. An approximately 22-centimeter-long insert barrel in .22 Long Rifle caliber (but also available in 5.6x35 R), which could be easily mounted by the user and produced acceptable groupings of 5-6 centimeters at 100 meters. It is still in use and costs about 80 euro. Other inventions based on Krieghoff patents include a single trigger design and a striking piece safety for hammerless guns. The latter design in particular won several awards. But where there is light, there is also shadow: the first hammerless side-by-side shotgun or an air-filled rubber cushion in the buttstock area proved to be flops. On the other hand, Duralumin is still used in gun manufacturing and a separate hand cocking system is still in use today, both in-house patents.

Krieghoff in wartime from 1939: From hunting guns production to flare pistols and anti-tank rifles

Before the production of hunting guns was discontinued at the beginning of the war in 1939, Krieghoff in Suhl manufactured no less than 71 different hunting models. At that time, the drilling was the most important gun type and made the company famous. Krieghoff was also "not innocent" during wartime, especially when judged by today's standards. Heinrich Krieghoff (1925, Suhl): "100 years ago, the state recognized that weapons were as necessary as bread to maintain existence. Today the state and its government may think differently. But as long as the pacifist dreams have not yet become reality, as long as the preservation and activity of individual existence is as much a struggle as the self-preservation of a state, as long as might is right, then weapons will be necessary to succeed in the struggle, to preserve existence and bring it to fruition." In 1934, Heinrich Krieghoff personally demonstrated a self-loading rifle in 8x57 J (but it was also available in 8x60 Magnum) to army leaders, who were impressed. However, due to minor design issues and high manufacturing costs, larger military trials never took place. During the war, Krieghoff employed many people, unfortunately also several forced laborers. They produced armament materials important to the war effort, such as the flare pistols popular with collectors today, the Luftwaffe Drilling, and the legendary Luger Parabellum 08 pistols (number of pieces: about 10,000). Also in the experimental stage were the MG 143 light machine gun and the PzB 40 (K) anti-tank rifle, manufactured by Krieghoff's master craftsmen and technicians. Other weapons, such as the MG 15 aircraft guns or the MG 151, reached the production stage and entered service. In wartime, they often bore the secret abbreviation "fzl" and can still be identified by this today.

Krieghoff: everything back to square one after the Second World War from 1945 onwards

The entire production facilities in Suhl were blown up by the Russian occupying forces at Whitsun, 1947, with parts of the plant having been dismantled beforehand and requisitioned for shipment to the East. Heinrich Krieghoff, his family and some of his closest employees were forcibly evacuated by the Americans to Heidenheim/Brenz, about 50 km north of Ulm. At first, weapons production was out of the question in Heidenheim; it was strictly forbidden. So the small Krieghoff group kept its head above water with the greatest of difficulty by doing whatever they could. This included, for example, the manufacture of washboards, small wooden boxes and pieces of furniture. Necessity is the mother of invention: Krieghoff saw the vast quantities of empty tin cans that the Americans had to dispose of and made hinges from them. The workforce collected the cans according to plan, then in further work steps quite usable fittings were manufactured. With just under 13 men, they produced up to 5,000 hinges a day, which indicates a real talent for improvisation, since everything was done by hand. From these first profits came the first tools and machines for the coming new start. From week to week, things went better, and then the son Heinz-Ulrich came home from war captivity, who first completed an apprenticeship as a machinist and toolmaker and then joined his father's company in the following years. After the currency reform, sales dropped for a short time, so that for a few years the company entered into a cooperation with the watchmaker Coufal, manufacturing and selling timepieces. The team proved to be very adaptive, and in just a few weeks, they built precise models that are still in use by collectors today. A true stroke of luck: the long-awaited re-entry into the familiar profession began with the conversion of Wehrmacht rifles into individual hunting guns, on request and with special permission from the U.S. Command. Thus, numerous bolt-action rifles, primarily supplied by the American occupation forces, were converted. In addition, the company made a name for itself with the manufacture and correct fitting of scope mounts. The first workshop, actually a converted apartment, in Heidenheim was soon too small for this purpose.

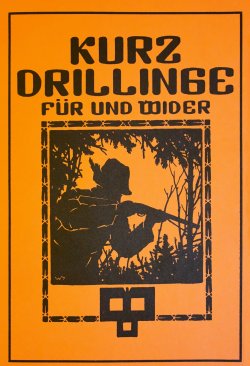

The 1950s: Krieghoff, the specialist for short drillingse

The gradual liberalization of hunting and firearms laws helped the further development of the company, that devoted itself again to the core competence. In 1953, based on orders from the State Forestry Administration, the production of combination guns - namely the so-called "Försterdrillingen" – was started again. These are in the tradition of the Krieghoff short drillings with 55-centimeter long barrels. A successful model, light and easy to handle, developed in the 1930s with the help of Heinrich Koppman, one of the best shooters and technical writers of his time. While other manufacturers preferred 28" or even 30" barrels according to the English example, Koppman went his own way. Even a good 100 years ago, people knew: "At the time of black powder, long barrels had their justification. However, they had the major disadvantage of making guns unwieldy and front-heavy, especially with drillings. This is no longer necessary today, but many manufacturers still traditionally stick to it. Many years ago, the designer Schrader wanted to eliminate this drawback by making the barrel shorter than shotgun barrels. Master Frank, on the other hand, wanted to make the barrel detachable to reduce packing size. Both inventions were doomed to failure. When we at Krieghoff in the testing department, starting in 1920, began to shorten the drillings from the former 68 centimeters to 66 centimeters, to 55 centimeters and later even to 50 centimeters, we ourselves did not believe in success at first. The opinion that a short barrel could not shoot well was too deeply rooted in our minds. Suggestions for this came from various quarters, first from customers who ordered them this way, which we ourselves dismissed as a curiosity. Then the engineer Schmuderer and the state forester Steingraß came, proved this from the technical and practical side and we went freshly to work. We had some failures in the beginning when we simply shortened the existing barrels, but then we made special barrels that also fit from the dimensions and the calculations. That brought the breakthrough. Immediately, we had the same good results on the stand and in the woods as with the long models, with all the advantages of handiness. The fact that hitting accuracy is not noticeably affected was brought about by a series of tests in which an 8-mm barrel was shortened from 70 centimeters, step by step, to 55 centimeters, which had no effect on the groupings. Such a little drilling is a boon when stalking and even more so when driven hunting." These facts are still valid today, even if the disadvantages such as the shortening of the sight radius, the amplification of the muzzle flash with fast calibers, the increase of recoil and "bang" must not be concealed. Even today, Krieghoff offers the shortest guns in series production of all major manufacturers – 55 or 60 centimeters as standard – and their success proves them right.

From 1960: Krieghoff's new start in Ulm and around Ulm

The actual new beginning started with the move to Ulm, initially to rented premises in the Upper Danube area. This was initiated by the then city building director Guther, who also wisely brought the Walther and Anschütz arms companies to the city. First of all, they allowed the production of air rifles again and so they started their production with 13 employees. As early as 1960, the company opened its own building in Boschstraße, the current company headquarters, which has been expanded several times in the meantime. The "Trumpf" and "Neptun" drilling models developed in the 1960s and 1970s, as well as the "Einschloss" and "Alb" combination gun models, and later the "Teck" and "Ulm" models, were particularly responsible for the successful business development. In addition to the manufacturing of hunting guns, the expansion of the product range to include clay shooting shotguns for the disciplines of trap, skeet and sporting played a significant role in Krieghoff's business development. Here, for example, the legendary K-32 shotgun should be mentioned. From the mid-1970s, the "computer revolution" also made its appearance at Krieghoff. Initially, electronic data processing was introduced in the commercial area in order to cope with the ever-increasing volumes of data and to improve production processes. But also in the technical area, new manufacturing techniques were introduced from the beginning of the 1980s. CNC-controlled machine tools, computer-aided design and manufacturing are now indispensable, not least because of the high complexity of the production catalog. There was a short guest performance in Suhl, when Krieghoff returned to Thuringia with a branch after the reunification in 1990. The intention was to continue old traditions and a large market was expected. Unfortunately, despite great organizational skills, it was not possible to run two plants at the same time and so the project was discontinued again after the turn of the millennium. Today, the "H. Krieghoff GmbH" is already managed in the fifth generation by the managing partner Phil Krieghoff with currently about 80 employees. The manufacturing plant is located exclusively in Ulm, although service for the US market is carried out in the USA with around 25 employees.

This series on the corporate history of Krieghoff Hunting and Sporting Guns continues here on all4shooters.com, ending with an overview of modern gun manufacturing in Ulm, Germany, as well as an overview of the current product line.

Photos: Dr. Frank, B. Metzner, Manufacturer's Archive