It is not easy to find companies that are willing to invest money in times of crisis. However, Beretta, which has achieved the synthesis of years of efforts in honing the project, following a detailed research of the technical characteristics of this DT11, did. This was not an easy job, because the already existing DT10 was still used by the best competition shooters with excellent results. In fact, the DT10 is the Beretta gun that has reached international success becoming a standard to which all other must compare, but we think that this DT11 will certainly exceed it.

Moreover, some solutions were anticipated by the Anniversary version of the DT10. So, this is not a revolution, which is inconceivable in an already class-leading product, but a continuous and constant evolution that takes advantage of the Beretta Team shooters acting as market antennas and representing the synthesis of a constant osmosis between all the design and production sectors, including the military.

This latter reference does not seem out of place, because products intended for the military sector must ensure complete reliability under the worst weather conditions and with maintenance reduced to a minimum or often not even carried out.

The characteristics anticipated by the Anniversary version of the DT10 are the wide receiver and the Steelium Pro barrel.

First things first, because Beretta has in place a thorough review of the way of working that will make the company maintain a role of excellency among weapon manufacturers.

In fact, if it is difficult to become a leader, it is even more difficult to remain so, as noted by Richard Trichilo, director of the weapon division at Beretta. It all started a few years ago with what the company calls “sturdy design”. This means that after the CAD drawing stage, the project passes through stages of calculation and simulation in order to create a prototype in the worst possible scenario, using the wrong side of tolerances and the highest acceptable deviation from the drivers, namely the fundamental variables.

The prototype goes to the ballistic laboratories and after the test benches, one parameter at a time is varied and, if necessary, the project returns to the CAD drawing.

This is what the sturdy design is about. It starts from the requisites signaled by the marketing and commercial department.

The prototype provides a complete validation of the project: these are followed by the validation of the product and the production process, which happens before passing to production. From a technical point of view, the result of this process is a firearm with durability and consistent performance over time.

The part that is most subject to wear in a competition gun is the cross barrel.

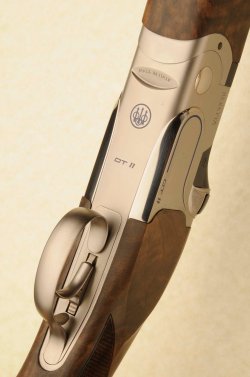

The DT11 has a replaceable cross made of high superficial resistance material for an optimum lock for the entire life of the gun. There are also a breech lock with transverse latching pin, the replaceable locking shoulders of the barrel, the nickel surface finish and the generous thickness of the extractors. But this should not obscure the great added value embedded in the construction of this rifle: the competence and skill of the human hand that builds it.

About half of the total work is made up of manual operations, which for the most part, but not completely, are devoted to finishing. It is no coincidence that the DT11 is assembled in the Premium department, the same department where the exceptional SO10 are made.

Great importance has been given to aesthetics: The DT11 is immediately identifiable in its rack. The receiver is extremely sturdy and heavy since it is 3 mm larger than the one from the DT10.

The increase in width resulted in an accurately computed increase in weight: 50 grams ‒ twenty grams in wood and 30 in metal ‒ all gathered around the center of gravity, to ensure a perfect balance and swing of the weapon.

The contrast between the satin finish of the receiver breast, the mirrored sides and the shiny profiles creates an immediately identifiable Unicum; the logo is reproduced in blue. If the newly designed guards of the upper rib, the butt of the upper part of the platform base, the new design of the opening key and the barrel selector contribute to an immediate identification of the model, no matter from what point of view it is present.

If aesthetics are important and if the solutions above are too many, we should not forget that the most important components of a gun, either superimposed or juxtaposed, are the barrels. In this model they are benefited by both the hollow pylons of the upper rib, to better disperse the heat, as well as the Steelium technology.

Basically, the traditional fitting cones are not present.

From the point of where the crimp closure of the cartridge case develops, the boring is uniformly conical and progressively narrows to about 150 mm from the muzzle. At this point the barrels become cylindrical with a boring diameter of 19.6 mm to then meet the Optima Bore chokes.

Now, the Steelium Pro barrels, which are within and on the better end of the tolerances, and are already suited to the use of steel shot as proven by the Proof mark impressed by the Proofing House, will only be used in manufacturing products of excellence, starting from the DT11 all the way up to the S010.

To be clear: the long cones in the bore are not new – I remember seeing them on a 1911 vintage Scott smoothbore – and the wide bores are not new either, since the shaft diameter of 19.6 mm, within the tolerances of the English bores for 12 calibers, was established at the 1907 Birmingham conference.

However, here we have a system created after extensive testing, suitable for industrial production with an innovation that can not be seen but that is very important and, above all, has been confirmed by the shooters who were randomly given, as an alternative and unbeknownst to them, Steelium Pro barrels instead of “normal” barrels.

Furthermore, the manufacturing process is unique and takes place in 18 steps, the last being the surface blue finishing.The round stock is subjected to deep boring followed by trimming, stress relief in the oven and internal polishing; then, they are applied to the inner profile for the cold hammering following new stress relief.

The barrels are not chromed but subject to a process of nitro carburizing; chromium is not used in the process and this gives significant environmental benefits.

The result of this new barrel concept, as indicated by the shooters who blind tested them, translates into a clear perception of a reduced muzzle climb, also owing to the center of gravity placement on the DT11 that is on the extension of the axis of the first barrel, an increased shooting stability that leads to increased speed and precision in the second shot – the one that wins competitions – and, finally, in the best performance of penetration and rupture of the skeet.

The Beretta DT11 is manufactured in different versions suitable to each type of specialty, by changing the impact point. As a matter of fact, the Trap, Skeet and Sporting models generate a central impact point, the American Trap model is characterized for a higher impact point.

For all versions, the flat hammer springs are V-shaped and provide high-speed percussion; the release of the firing mechanism happens in maximum security with an open gun.

The grade 3 walnut pistol grip and handguard checkering, is achieved by hand; the owner can choose the final finish of the wood between oil, wax or tru-oil.

It is a logical consequence of managing a product, at all manufacturing stages, such as a Beretta luxury smoothbore, each of which is personally supervised during the production by the companyʼs Master Gunsmiths.

This is not secondary, as we are dealing with the oldest gun factory in the world.