For reloaders, the .45 ACP or .45 Auto is probably one of the best-known and most popular handgun cartridges. Introduced in 1905, it was intended to replace the .38 cartridge in the US Army, which was perceived to be too weak. The .45 ACP was the favorite of military and law enforcement agencies for many decades, until it was replaced in many places by the 9mm Luger. Sport shooters and reloaders are well aware of its qualities. The cartridge is considered accurate and reliable. Last but not least, it is great fun for target shooting because the large holes are more impressive than those of a 9 mm Luger. The disadvantage of big calibers is the high cost of ammo for intensive training. But this can be greatly reduced by reloading and with a careful selection of components, while accuracy can often be improved. With good and inexpensive bullets, powders and primers, a good 1000 cartridges can be made for less than 200 euros.

Reloading handgun ammo: in the beginning...

...is the careful selection of components. An almost infinite number of bullet shapes, weights, various powders, primers and cases are available. According to the testers' experience, good accuracy can be achieved with many good quality bullets when the proper tuning work is done. However, excellent accuracy – that is groupings below 1.2”/30 mm at 25 meters – requires a very careful selection, a lot of time at the Ransom Rest, and high-quality bullets as well as as primers. Another prerequisite for such good results is a gun that basically delivers such results. Fortunately, there are many empirical values, so not every reloader has to start from scratch. The shooter should ask himself the honest question of what accuracy he/she can achieve. Anyone who is a real precision shooter should also use training ammo that holds at least the 10 ring of the precision target – so at least 2”/50, better 1.5”/40 mm groupings at 25 m. This is the only way to improve skills via feedback – if the hits are where they are supposed to be. If, on the other hand, the shooter is not so accurate, he may be better served for the time being with ammo that achieves 2”/50 to 2.4”/60 mm groupings but is considerably cheaper. While not exploiting the accuracy of expensive loadings to his/her advantage, he/she can convert the money saved into higher quantity, which will also improve shooting skills.

The .45 bullet when reloading

Who has the choice, has the agony. The choice of bullets is varied. From light to heavy, from greased or coated lead to the very expensive hollow point jacketed bullets. But which type is the right one? The first question is the weight. For precision shooting, lightweight 185 or 200 grain bullets are preferred. Many reloaders choose SWC bullets. The advantage is obvious: the rim of the bullet punches beautiful holes that show the exact diameter of the projectile. In the case of the .45 ACP, this is a tidy 11.45 mm. The large projectile thus represents a real competitive advantage in competitions with a free choice of caliber. Discussions about the use of a bullet hole tester are no longer necessary: the sharply punched holes are easy to evaluate. The disadvantage of this sharp-edged bullet shape is that some guns have feeding problems with it, or the bullets may be pressed obliquely into the case with a wrong setting die. Truncated cone or round nose bullets often do not lag in accuracy and feed better. However, the holes on the target do not look nearly as nice. Round nose or truncated cone bullets often produce holes similar to those of a 9mm or .357. There is a difference of opinion when it comes to coating: greased lead bullets usually produce narrow groupings and are relatively inexpensive. The disadvantage is the smoke and odor in indoor shooting ranges. Accurate jacketed bullets are very uniform, but usually more expensive and not as gentle on the barrel as lead. Coated lead bullets offer a good as well as inexpensive option.

.45 Auto cases and their material

The case material plays a role that should not be underestimated. High quality material from the same manufacturer is recommended. Lot uniformity is not a must, but also not a mistake.

Very important in the selection is the hardness of the brass. It is determined by the proportion of copper. A proven mix is the Ms72 alloy, which is 72 parts copper and 28 parts zinc. For soft, i.e. lead bullets, the case grades with a higher copper content prove their worth as they are softer.

A uniform crimp, i.e. the contact of the case mouth with the bullet, is only ensured by cases of the same length. Ideally, the cases are once-fired and cleaned in a wet tumbler. This time-consuming method is not suitable for intensive shooters.

The right powder for handgun cartridges

Nothing works without powder in the case. While the selection is not as wide as for bullets, there are some rules to follow. For light bullets up to 200 grains, as primarily treated here, fast-burning powders are recommended, such as Vihtavuori N310 or N320, Hodgdon HP38 or Titegroup, Alliant Red Dot as well as Bullseye. Above 200 grains, the somewhat slower-burning progressive grades come into play.

Primers

While their influence on accuracy is present, in the handgun range it is less than the interaction between case, bullet and crimp. Nevertheless, attention should be paid to high-quality material. Nontox primers are a special case: their use usually results in a lower bullet velocity. The primer should be seated at least flat, preferably with a few hundredths of a millimeter of protrusion from the case head.

The loading process for the .45 ACP

Whether loading with a multi- or single-station press, the first operation is resizing. This presses the case to its original dimensions and removes the primer. The case must enter the die sufficiently deep, but it must not be sized too tightly either. The cartridge should not change its overall length after bullet seating, still without crimp, when the bullet is pressed firmly against the bench. No strong impression of the bullet should be visible on the outside of the case either. Next comes the new primer, then the case mouth is expanded. The principle of "as much as necessary, as little as possible": this protects the cartridge case and allows the bullet to be pressed into this very case without damage. Coated lead bullets are particularly sensitive to this.

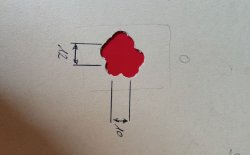

After filling in the correct amount of powder, the most important step follows: seating the bullet. The seat plug must match the bullet contour perfectly, otherwise the projectile will be crushed and accuracy will suffer. A meticulous check is worthwhile here. The right seat plug not only presses the bullet to the correct depth, it also aligns it axially with the case. Many seat plugs do not match every desired bullet contour as delivered, sometimes adjustment is necessary through careful reworking. Optimally adjusted, the length of the cartridges should only vary in the range of +/- 0.1 millimeters during reloading. Often, however, values of only 0.05 millimeters can be achieved.

The crimp: what is necessary for the .45 ACP?

Finally comes the crimp. A light taper crimp is usually enough for the .45 ACP. It should be strong enough so that the case mouth is at least flush with the bullet and the bullet is not pushed into the case by the cycling motion. In the case of cartridges with truncated cone bullets, a short barrel throat can result in a cartridge that looks correctly sized, but actually still not fitting into the chamber. A final check fully inserting the reloaded cartridge into the disassembled barrel is essential. A dummy cartridge with the maximum cartridge length for the particular bullet is a great help. A free-bore of at least 0.2 millimeters is desirable. If you want more freedom in cartridge length, have a gunsmith rework the barrel throat. A cartridge that is too long will stick into the rifling. This is not only detrimental to precision, but also exorbitantly increases the gas pressure. Slanted or coated bullets where the coating has been damaged in the seating process, are accuracy killers. When loading the popular HG-68 bullet shape, it is beneficial to gun function to allow the edge of the bullet to protrude slightly above the case mouth; this helps feed it into the chamber.

Conclusion: should I reload the .45 ACP?

The .45 ACP pistol cartridge is rightly described as good-natured. But it's not enough to mix reasonably matched cases, bullets and powders. It's hard to make bad loadings, but it remains a challenge to develop excellent loadings for this caliber. The consensus is that the .45 is one of the nicest calibers to shoot as well as load. The big calibers are fun to shoot. And when reloaded, they are excellent value for money compared to other handgun calibers. With this in mind, good shooting!

Text: Clemens Bolz & Alexander Schell, Robert Riegel

All loading data mentioned in the article is without guarantee! Every reloader acts on his own responsibility!