First of all, our special thanks go to a long-time friend of ours, Thomas Eckey of Gunworks. He provided us with his personal Barrett MRAD, modified in detail, in .338 Lapua Magnum with .300 Winchester Magnum interchangeable upper receiver. Among the features not found on the factory standard version are, of course, his in-house Gunworks muzzle brakes, which are as cleanly crafted as they are effective, or a practical alloy carry handle on the underside of the handguard. The Gunworks Thumb Vast 930 compensator is mounted on the .338 Lapua Magnum barrel and the Gunworks Thumb Vault 762 on the .300 Winchester Magnum barrel. Tilted ERA-TAC one-piece mounts as well as Schmidt & Bender PM II scopes also fit this top equipment.

MRAD by Barrett: a brief retrospective

Like a host of modern, modular sniper rifles with caliber/barrel interchangeability from prominent manufacturers, the Barrett MRAD came about as a result of the United States Special Operations Command (SOCOM) Precision Sniper Rifle (PSR) program launched in early 2009. As is well known, the Remington MSR (Modular Sniper Rifle) emerged as the winner of this competition in 2013. After PSR, the follow-on Advanced Sniper Rifle (ASR) solicitation appeared in 2016. For this, the US Department of Defense announced on March 11, 2019, that SOCOM was procuring an improved sniper rifle under the ASR solicitation with the special Barrett MRAD MK 22 ASR in .338 Norma Magnum with interchangeable kits in .300 Norma Magnum and 7.62x51 mm NATO. For Barrett, the award meant a five-year contract running through 2024 worth $49,936,300. For completeness, the Barrett MRAD MK 22 is topped by a Leupold Mark 5HD 5-25x56 scope with Flat Dark Earth (FDE) surface coating and patented Mil-Grid reticle. Developed by Chris Barrett and released in 2011, the MRAD is based in technology on the Barrett Model 98B "Bravo" in .338 Lapua Magnum introduced in 2008. Unlike that predecessor, however, it has a folding stock and is convertible in terms of caliber and barrel length. The manufacturer from Murfreesboro, Tennessee, carries three different MRAD rifle models in its catalog. In addition to the classic MRAD, there is the simplified MRAD SMR (Single Mission Rifle) without folding stock, quick length adjustment and caliber/barrel change option, both available in seven calibers: .338 Lapua Magnum, .338 Norma Magnum, .300 Norma Magnum, . 300 PRC, .300 Winchester Magnum, .308 Winchester and 6.5 Creedmoor, as well as the MRAD MK 22 model, which is largely identical to the military ASR original and is offered only in .338 Norma Magnum, .300 Norma Magnum and 7.62x51 calibers. The MRAD and MRAD SMR are available with 17"/432mm (.308 Win. only), 24"/610mm and 26"/660mm barrel lengths. The MRAD MK 22, on the other hand, is available with 27"/686 mm (.338 NM), 26"/660 mm (.300 NM) and 20"/508 mm (7.62x51) barrel lengths.

The MRAD in monolithic AR design

Wie weitere bekannte Like other well-known light alloy chassis precision rifles – such as Ruger Precision Rifle or the Unique Alpine UPG-1 – the Barrett MRAD, with its straight "in-line" design and two-piece receiver, cannot deny a certain kinship with Eugene Stoner's AR-10/AR-15. The grip section and the upper receiver with integral handguard made of 7075 aluminum surface-finished to military standards are connected to each other via a front hinge pin in the area of the lush magazine well, so that the MRAD can be opened up like an AR rifle. But the differences are in the details: instead of another simple pin in the rear of the grip, a more elaborate, wedge-shaped latch mechanism provides a more solid connection between the two main components, which, given the powerful .338 Lapua Magnum long-range caliber, also ensures the necessary resistance in continuous use. The locking mechanism between the grip and the receiver can only be released when the bolt is open by means of a lever on the underside of the grip. When the bolt is closed, the connecting mechanism of the two main assemblies is blocked.

Interchangeable receiver or interchangeable barrel

Barrett chose the AR-inspired design method because it allows the bolt action to be caliber converted without loosening a single screw on the rifle. If you use a complete interchangeable receiver with optics mounted on it and zeroed in, you are ready to go immediately after a caliber change without re-zeroing or further effort. Of course, a complete Barrett-MRAD exchange system, as it was available to us, is the expensive luxury solution. A cheaper way is to change the barrel, which only requires loosening two T30 Torx screws on the receiver/handguard to pull the barrel forward out through the integral handguard. The barrel featuring a very solid barrel extension with a diameter of almost 38 millimeters and AR-typical barrel nut is locked in the receiver on a clamping surface of 87 millimeters. This solid construction is also necessary to support the 2.6-kg carbon steel barrel in the chassis and to positively influence the barrel vibration behavior. The barrel, which tapers from its root to its muzzle, has eight flutes that increase its surface area. This ensures better heat dissipation and faster cooling of the hot-shot barrel. However, due to the increased surface area of the jacket, barrel mirage sets in earlier and makes it more difficult to see through the optics. And that happens quickly when up to six grams of nitro powder are burnt with each shot, heating up the barrel. The 26"/660-mm barrel in .338 LM has a 1-9.4" twist and a ¾x24 UNEF muzzle thread, while the same-length barrel in .300 WM has a 1-8" twist and a ⅝x24 muzzle thread. As mentioned earlier, the original Barrett compensators with two expansion chambers were replaced with Gunworks muzzle attachments. Although holes or areas for gas relief are not directly visible on the receiver, the MRAD still has appropriate safety features. After barrel disassembly, one discovers generously sized milled holes in the housing directly behind the cartridge chamber, which direct the gas away from the shooter downward in the event of overpressure.

Polymer bolt guides of the MRAD

The bolt, which locks with nine tri-lug design lugs in the barrel extension, reveals another design feature of the Barrett MRAD sniper rifle: two polymer tubes known as the "Rear Bolt Guide" and "Front Bolt Guide" that serve both as dust covers and guides for the bolt, whose locking head can be quickly replaced by removing a cylindrical pin. These construction features ultimately also support more rational production in view of the wide range of calibers.

The MRAD chassis with comfort

piece height.

The basic design of the top assembly including upper receiver and handguard, which is made of one piece of light metal, is conceived for maximum stability. There are neither KeyMod nor M-LOK interfaces on the handguard, but an in-house system for attaching short mounting rails and additional equipment. The stock, which folds to the right side of the rifle, not only features an ultra-rugged hinge joint, but also shines with adjustment mechanisms for customizing the MRAD to the individual shooter. If the right-hand star knob screw is loosened, the cheek rest can be varied in height by up to 30 millimeters. The butt plate can be individually adjusted in length by up to 40 millimeters in seven steps at the touch of a button. The detent surfaces of the adjustment mechanisms are generously dimensioned and thus shot-resistant even in continuous use. A height-adjustable butt plate is not available, but this is perfectly acceptable for a rifle with a straight AR design, since the buttstock is positioned higher than on a conventional bolt-action rifle anyway. This means that even in prone and kneeling positions, there are no problems when you want to tuck the rifle into your shoulder. The stock is rounded out by a free-standing Magpul MIAD pistol grip. In the grip of our test gun sat a Barrett double-stage trigger with a measured pull weight of 2300 grams. That doesn't sound that low, but the trigger had perfect characteristics and about 2000 grams were already used up in the pre-travel, leaving only about 300 grams for the actual shot release. The controls on the grip can be mounted on either the left or right side of the gun. This is especially practical for the 45-degree rotating safety lever. If you mount it on the left side as a right-handed shooter, you can not only operate it perfectly when firing, but also use it as a thumb rest when shooting. The aim is to divert the forces generated in the right hand in a straight line to the rear of the rifle. When the thumb encloses the grip, it is inevitably pushed to the right by the movement of the trigger finger, and barely perceptible trigger pull errors occur. For this reason, this safety was also designed with an oversized surface that provides a perfect rest. The Barrett MRAD is fed by double-stack box magazines made of polymer with a capacity of 10 cartridges.

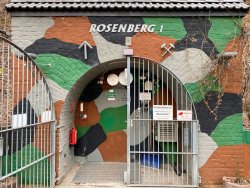

Indoor shooting range at 500 m

For test firing we went to Marienberg, in the Ore Mountains in Saxony, Germany, not far from the Czech border. Living up to its name, the Ore Mountains are known for deposits of ores such as silver, copper, nickel, tin and uranium, and the locals can look back on a centuries-old mining tradition. Today's shooting range was originally built in the 1960s as part of a water supply from a dam to Karl-Marx-Stadt (now Chemnitz). How long mining has been anchored here is proven by the fact that the side tunnels were built here as early as 1332. However, since the water supply project was abandoned, it was not until 2012 that the gallery was reopened, and with it the idea of building a shooting range germinated. A lot of work had to be done before the shooting range could be opened in 2015. At the shooting range there is an electronic evaluation system from the Silver Mountain Target company, so that the hit images as well as the bullet velocities at 100, 300 and 500 meters can be recorded. It is then possible to view a comparison of the grouping circles at different distances for a shot group. This saves time and money. In connection with the bullet velocity at different distances, it is therefore possible to work scientifically-analytically. Skeptics will point out that the wind influences, which are the proverbial salt in the soup in long-range shooting, are completely absent here. Nevertheless, this is the best place to test the performance of a firearm/ammunition combination.

With the Barrett sniper rifle on the shooting range

We divided the practical test into two parts. The first test was about collecting the ballistic data of the cartridges at 100 meters, so that we could then use it to go to the 500-meter range in Marienberg. Fully equipped, the Barrett MRAD weighed just under 8.5 kg. This means that nothing can upset the rifle when firing and the shooter only has to concentrate on the smooth, repeatable trigger action. The results achieved at 100 m already testified to this, as a 5-millimeter grouping with a .338 Lapua Magnum speaks for itself. This top result was achieved with the RWS 250-grain Target Elite Plus. After a quick change of uppers, we moved on to the .300 Winchester Magnum caliber. Here, too, a single-digit value was achieved as the top grouping – 9 millimeters, with Hornady 178-grain ELD Match factory ammunition. Then it was off to Marienberg in Saxony to further test the potential of the Barrett MRAD on site at 500 meters indoors. Because the ballistics of both cartridges are relatively similar at this distance, we only had to compensate for a difference in elevation of between 2.6 and 3.0 mrad for both receivers in order to hit the target 500 meters away. Here we were able to take advantage of the fact that both interchangeable receivers had appropriately zeroed optics, so a caliber change was implemented extremely quickly. As at 100 meters, the RWS Target Elite Plus in .338 Lapua Magnum also shone at 500 meters, as the best grouping measured 78 millimeters. With our handloaded cartridge, we even managed a 44 millimeter at this distance, with the complete group of 5 opened up by a flier to 109 millimeters. Even in .300 Winchester Magnum caliber, the best 100-yard cartridge also shot the best 500-yard result, which experience shows is by no means always the case. Thus, cartridges with modest 100-meter results can rise to top at long distances. With the Hornady 178-grain ELD Match factory ammo, which is a top performer at short ranges, we achieved a very respectable 86-mm group at 500 meters.

Barrett MRAD specs and price

| Model: | Barrett MRAD |

| Action: | 9-lug

bolt locking in the barrel extension |

| Barrel

(.300 WM): | 660 mm long fluted, with 1-8" twist, 5/8 x24 UNEF muzzle thread and Gunworks Thumb 762 Vault compensator (extra equipment, standard with Barrett compensator) |

| Barrel

(.338 LM): | 660 mm

fluted, with 1-9.4" twist, ¾x24 UNEF muzzle thread and Gunworks Thumb 930

Vast compensator (extra equipment, standard with Barrett compensator) |

| Stock: | Light

alloy chassis with folding, versatile adjustable buttstock, free-standing

Magpul IAD pistol grip and integral handguard with mounting options for QD

sling swivels and other extra equipment |

| Magazine: | Double-stack box magazine made of synthetic material with a capacity of 10 rounds |

| Trigger: | Barrett

double-stage trigger; measured trigger pull weight: 2350 grams |

| Safety: | two-position

45-degree safety on the grip, which can be mounted on either side and acts on

the trigger |

| Overall

Length: | 125.5 cm-105 cm (with buttstock extended to maximum and folded) |

| Weight: | 6600

grams |

| Price: | 7449 euro |

Barrett MRAD: wrap-up

The Barrett MRAD multi-caliber sniper rifle can fully score in all practice-relevant areas: a very well thought-out, robust design and a high level of workmanship coupled with the best handling, function as well as accuracy leave nothing to be desired. However, the standard version of the rifle, which is available with a black, gray or "Flat Dark Earth" (FDE) finish, costs a hefty 7449 euros. The version with a lighter carbon barrel even costs 8349 euros. Nevertheless, it is unfortunately cool and worth every penny.

What we liked: | What we found less good: |

| Universal rifle thanks to multi-caliber capability | Very high price between 7449 and 8349 euros |

| High level of workmanship | |

| Outstanding accuracy | |

| Sophisticated

equipment concept |

Text: Stefan Perey, Tino Schmidt and Michael Fischer