By switching from aluminum to the new material titanium, EAW now saves another 20 percent in weight compared to the previous model. Nevertheless, the new titanium version is even more stable than its aluminum counterpart. According to Stefan Schilling, the managing director of EAW, this new form of mount manufacturing has already been patented and confirmed by a certificate.

Video: the new 3D-printed EAW mounts

Just like the 3D-printed aluminum mounts, the new models, made of titanium, are worked on modern 5-axis machining centers to meet self-imposed standards regarding tolerances. Despite more than 100 years of tradition as a producer of high-quality mounts of all kinds, EAW today also stands for innovation. The company is proud of the fact that this change has been successful. Stefan Schilling, the new owner, has played a major role in this. He, too, continues to rely on the German location of Würzburg, which is even immortalized as a defining element in the company name. No wonder, then, that the new 5-axis machining centers were also installed at the company's headquarters.

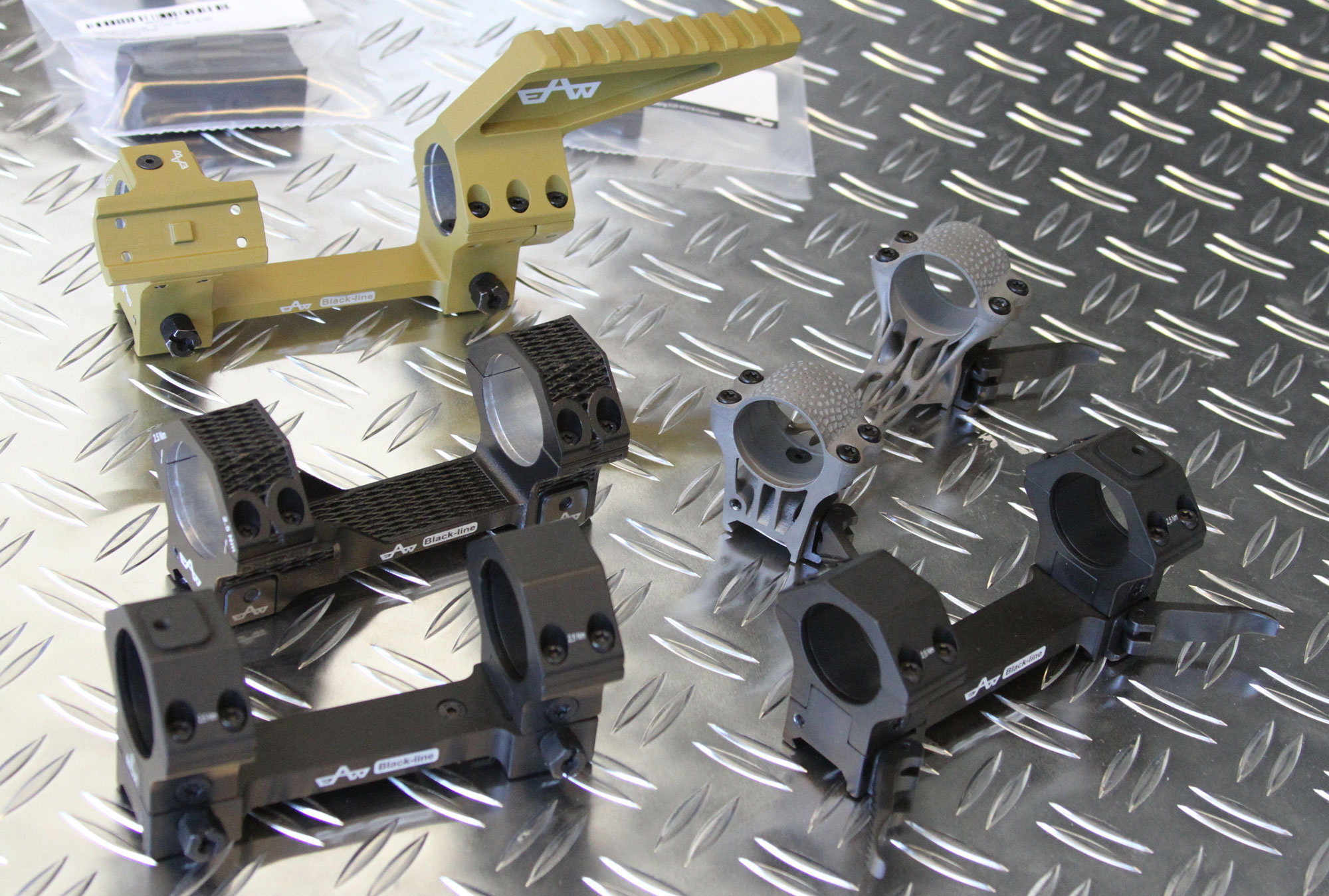

The latest highlight in the development of extremely lightweight target optics mounts – manufactured using 3D printing – comes from EAW

This process is also known as generative manufacturing. Generative because the material is applied layer by layer by the 3D printer, creating the finished mount step by step. This also applies to the titanium material and the new mount. The entire construction and design appears very delicate and yet this innovative mount withstands the extreme stresses to which a riflescope, and thus also the mount on the rifle, are exposed. Since "signed and sealed" is better than "good faith", EAW has also already had the new titanium model from the 3D printer tested by DEVA (German Experimental and Test Institute for Hunting and Sporting Firearms ). The manufacturer proudly shared the result with us: "The mount passed EAW's usual load test at the DEVA with flying colors in the first attempt. The mount showed no signs of wear after 2,000 shocks at 700 g. A lifetime test of 20,000 shocks or more is already being planned."

The bionic design of EAW's scope mount is an absolute world first

Despite its extremely low weight, this EAW mount also guarantees absolute robustness. "You can expect many more models in EAW's bionic structure in the future" – EAW informed us in a statement about the latest product.

The customers have the possibility to order also this 3D mount made of titanium as a fixed mount or as a repeatable variant with levers at EAW from now on. The model is available in 30 and 34 millimeter diameters.

To pre-order, please contact the manufacturer by e-mail at vertrieb@eaw.de, where you will also receive further individual information.

More information about EAW's mounts is available on the manufacturer's website.