This is how it may have happened in Malmö, Sweden, in 1974: technician, amateur hunter and former soldier Arne Ekstrand was shaving in the morning and suddenly noticed a point of light reflected from the shaving mirror on the wall behind him – and it remained in the same spot, even when he moved his head to the side. He had an idea that this light reflection could perhaps also be used for aiming a hunting rifle. After all, depending on the light conditions on the hunting ground or the user's eyesight, there were physical limits to open sights made of a rear sight and front sight, as well as riflescopes. The idea of light was of course not new, but had already been tried out for over a century. But without a powerful lighting element, users had to rely on passive light sources, such as glass or later plastic tubes, which collected ambient light and then illuminated the crosshairs. Experiments were also carried out with light-storing materials, such as in luminous numerals on a wristwatch. Ekstrand rethought the principle: an experimental model consisting of an empty toilet paper roll and a light-emitting diode soldered to two cables and powered by a battery was quickly developed. An LED (Light Emitting Diode) is an electronic semiconductor that emits light when current flows through it. This not only makes it much more compact than conventional light bulbs, it also consumes only minimal power and can also influence the color spectrum. However, Ekstrand lacked both the financial resources and the appropriate workshop to create a finished product that also had the precision adjustment mechanism required for a sight.

His acquaintance with a fellow countryman, electrical engineer Gunnar Sandberg, changed all that. He recognised the potential in Ekstrand's idea and was able to provide both the manufacturing capacity and the financial means to start small-scale series production through his company Elektro Sandberg, which he had already founded in 1959. A market for these innovative devices was not only conceivable for hunters, but also for marksmen – perhaps even for the military and police. The patent for the first commercially manufactured "Aimpoint Electronic" red dot sight was granted in February 1975, after which the company Aimpoint AB was founded.

Optical aiming aids for firearms had been experimented with since the 16th century. However, the basic problem of a lack of light in unfavourable visibility conditions could only be solved with artificial light. In the years after the First World War, optical devices were combined with electronic components for the first time. Immediately after the end of the war, the German companies Busch, Fuess and Voigtländer as well as the Prague factory of the brothers Jan and Josef Fric, worked on the development of illuminated reticles for scopes. At that time, these were still equipped with light bulbs, glass rods and dry batteries. Fuess probably developed an illuminator around 1920, which was mounted on a riflescope and used optical lenses to produce a focussed beam of light. The Berlin company Gerdes presented the so-called "Luxauge 28", a riflescope attachment that was powered by a pocket battery. However, as with other devices that require light to function, it was the miniaturisation of components and the development of LEDs that brought about a significant leap in development.

The Aimpoint principle revolutionised the aiming device market

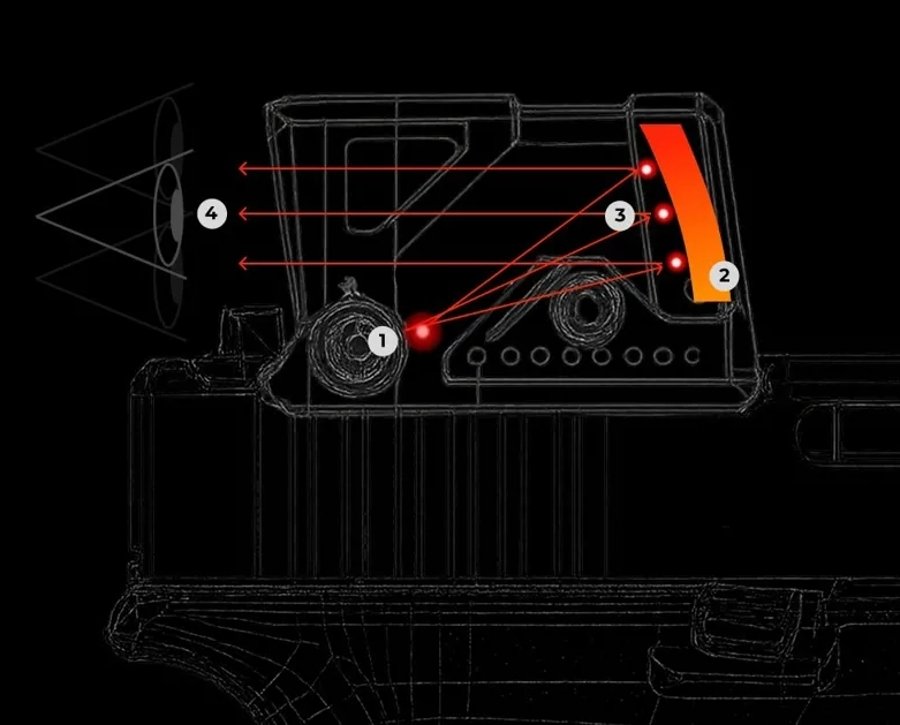

The functional principle of the original Aimpoint Electronic model, which was first presented in 1975, was based on placing a light dot from an LED in a riflescope tube instead of an unlit crosshair. And it worked in principle exactly the same way 50 years ago as it does today. However, an LED itself in the center of the target image would only produce a rough illuminated dot, far too imprecise for direct aiming. And where to put the connecting cable? The reflected light is therefore projected diagonally upwards against the front lens by a diode attached to the lower edge of the inner tube. This makes it technically possible to regulate the spot size, its roundness and also the light intensity via the power supply using a tiny diaphragm. At the end of the last millennium, the brighter XD light-emitting diodes were used for a while, whose dots were easier to recognise in bright sunlight. These models were labelled with the abbreviation "XD" (they were also the first to receive a 10-year guarantee at the time).

As the slightly curved lens is slightly tilted back upwards (as is the case with all red dot sights today, regardless of manufacturer), the reflected dot is sent in a straight line to the shooter's eye according to the principle of "entry angle equals exit angle". The optically high-quality, coated and naturally distortion-free lens material must therefore not be completely reflective, but must be semi-translucent: on the one hand, you want to recognise the target through the glass, and on the other hand, the LED light (currently in the wave range of 650 nm) must be reflected into the shooter's eye.

You don't even have to look through the center of the tube – as with Ekstrand's shaving mirror. It is sufficient to align the illuminated dot and the target, which happens without parallax so to speak (to put it simply, because some optical laws are not so easy to override, but it works for common shooting distances). The fact that half a century later, specimens from this first series of the Electronic from the 1970s are still in use around the world may testify to the high manufacturing quality and utility value.

As early as 1980, the fledgling company Aimpoint received its first military order and the Swedish Army received the robust Aimpointacs aiming device. Nevertheless, the innovative light-emitting diode tubes remained an insider tip among hunters and sport shooters for several years, even though the top model Aimpoint 3000, which had been improved several times, was honoured as "Optical Product of the Year" at the SHOT Show in 1988. The success in the military sector (because profitable orders with high unit numbers only come from there) came more by chance when US General Norman Schwartzkopf was filmed by a TV crew during the Second Gulf War in 1991. And his elite soldiers, who were not in uniform but in civilian clothes, also attracted the attention of the military experts watching around the world, as the assault rifles carried Aimpoint sights that the troops had procured privately. In 1997, after rigorous testing, the US Army officially ordered 80,000 of the Aimpoint Comp4 model for the first time, which entered service as the M68CCO (Close Combat Optic). France followed suit with 10,000 devices, and other armies and LE units around the world followed suit.

Success and expansion: Aimpoint's path to global market leader

Consequently, Aimpoint Inc. was founded as a subsidiary in the USA in 2002, and one year later Lennart Ljungfelt became CEO of Aimpoint – a position he held for over two decades until the anniversary year 2025, when he handed over the management of the Group to Per Lovatt (see box). Inventor Arne Ekstrand lived to see this positive development: he died in 2004 at the age of 84. Under Ljungfelt's leadership, the company experienced stability and yet further growth. Aimpoint received its largest military order in 2007, when the US Army ordered 565,000 Aimpoint Comp M4s. In the same year, a new generation of devices was introduced (initially) for the civilian market with the small Aimpoint Micro, which was significantly easier to handle than the usual long tube models and (also with the further development from 2014) opened up new customer groups and possible applications.

This was followed in 2018 by the Aimpoint Acro, an even smaller aiming device originally designed for handguns, which was optimised in its current version as the Acro 2 in 2021. The Aimpoint Acro is probably the smallest "red dot" to date with an enclosed housing, making it rugged and, above all, dust and water resistant.

The total number of Aimpoint devices manufactured today is well over five million. Twelve different lines of devices are currently manufactured, which can be mounted on rifles and shotguns, handguns and service semi-automatic rifles, depending on the intended use. The Acro S-2 is a sight designed for shotguns, which attaches in the center of the top rib and has a particularly large and quickly detectable illuminated aiming point ("dot") with a diameter of 9 MOA due to the large eye relief and for aiming at flying clay targets (or at flying game for hunting). Depending on the intended use, a different dot size of 2, 4, 6 or even 9 MOA is also available depending on the Aimpoint model. The most recent cooperation with a gun manufacturer at the beginning of 2025 was the COA sight, with which the Austrian gun manufacturer Glock equips five popular 9mm pistol models. The COA sight is mounted directly without additional adapter plates – the mini red dot sight is supported at the front objective lens with a nose inserted in a slide recess, similar to a ski boot binding. This brings the advantages of a lower sight line as well co-witnessing with the mechanical sights at standard height. This means you can use the red dot or the classic rear sight/front sight without having to rethink. The COA is also narrower than even the Acro and forms a slim, coherent unit with the pistol without any disturbing corners or edges. The Swedes created a new automated production line, which was put into operation at the same time, for the manufacture and presumed sales success. Presumably, the COAs will therefore also be available for other types of guns at a later date.

Overview of the Aimpoint model series

Without claiming to be complete and leaving out variants, here are the most important series still in production at Aimpoint. All are basically without magnifying lenses and they have various brightness settings, some also have settings for night vision devices so that the dots do not dazzle:

- Acro: After the COA, the smallest enclosed red dot sights in box form, as version S-2 for shotguns, as C-2 or P-2 for handguns and other firearm platforms.

- Micro: Compact and short devices in tubular form, suitable for almost all types of guns with corresponding mounts.

- Hunter: With 30- or 34-mm tubes in short or long versions for hunting use, usually mounted with two separate rings.

- 9000: All-round models, classic two-ring mounting, mechanical adjustment of the dot.

- Comp: For professional use, very rugged, very light.

- PRO: "Patrol Rifle Optic", a compact and affordable device for LE/military use.

- Duty RDS: With a bright 2 MOA dot, ideal for short and medium target distances. All adjustment options flush and waterproof.

In the spirit of customer service, the Aimpoint website also contains data on devices that are no longer in production, the respective manual downloads and (provided they were discontinued no more than ten years ago) individual parts can also be ordered. Even though there have been almost countless other manufacturers and suppliers of red dot sights worldwide for years, Aimpoint, in addition to its status as the inventor, has also initiated the triumphant advance of red dot sights, which today occupy a firm place alongside scopes among aiming aids worldwide and have largely pushed the classic open sights consisting of rear and front sights back into certain niche areas, which are usually specified by regulations.

Pros & cons of Aimpoint red dots: what are the differences to a riflescope or open sights?

Let us therefore conclude by looking at the advantages and disadvantages of the aiming devices. Riflescopes have magnifying lens systems and are particularly suitable for shooting at distant targets from around 100 metres, which can also be "zoomed in" even closer with variable scopes. However, this requires the non-aiming eye to be closed, which means that the brain can take in less information about the surroundings. Otherwise, both eyes would see different views of the target. Scopes are only parallax-free at a certain distance, otherwise the parallax must be adjusted using an additional wheel. A fixed eye relief is mandatory, even if nowadays a larger "eyebox" allows a little more leeway in the head position. Riflescopes are more suitable for a steady shot from a raised hide or for precision shooting from a bipod or sandbag. The riflescopes with smaller or even single magnification (approx. 1-6x24) used for driven hunts, for example, are essentially a transitional solution for shorter ranges because they simulate the advantages of a red dot sight.

With red dot or illuminated dot sights (nowadays other dot colors are often available), precisely because they deliberately work without any magnification, you can always aim and shoot with both eyes open: this facilitates orientation and a sense of balance "in space", especially with moving targets in action shooting or hunting. The shooter sees the target with both eyes as well as the aiming point in front of the right or left eye, depending on the shooting stance. And both are combined in the brain to form a coherent target image. As already mentioned at the beginning, these devices are parallax-free, so it is sufficient if the illuminated dot and the target match. But, of course, only if one doesn't make any errors following aiming, such as when pulling the trigger.

An important feature is that all Aimpoints work in enclosed housings, even if these have different diameters and lengths depending on the model. If you delve deeper into the variety of models, the question arises as to why there are no variants with an open LED that shines onto a lens mounted in front of it. Although such models are usually smaller, flatter and lighter, a housing protects the optical system from the effects of weather, dust and, in the case of handguns, hot powder gases, especially for professional use. Ever since Aimpoint started co-operating with military procurers, enclosed housings (even if they later became smaller and smaller) were the only option. There were indeed attempts: in the 1980s, for example, the ACS, a sight with an open emitter, was developed in co-operation with the Swedish Air Force for their J35 Draken fighter aircraft. However, it remained a prototype.

only 14 mm above the gun. It weighs 61 g,

has a 3.5 MOA red dot and the

battery lasts 50,000 hours.

Aimpoint's extensive product range not only lists aiming devices for all conceivable "end customers", but also mounting solutions for any conceivable special applications. For example, there are magnifiers such as the 3X-C with triple magnification, which can be combined with an Aimpoint mounted in front of it in the direction of fire. There are also various mounts for additional attachment (usually at a 45-degree angle) of an Aimpoint to a riflescope, so that special forces, but also action sports shooters with targets near and far, can switch between the two aiming devices. You can simply tilt the rifle slightly around the longitudinal axis and then aim using the red dot.

Success attracts envious people, as well as free riders: there are in fact numerous pirated copies of Aimpoint's successful models, some of which are no-name models, but some also have a counterfeit Aimpoint logo. The company therefore also lists information on its website on how to recognise such counterfeits: for example, the country of origin (all Aimpoints are still only manufactured in Sweden), the serial number or front lenses that are not reddish but appear to be different colors or are clear. The manufacturer has also abandoned the color trends of previous years: with a few exceptions, all Aimpoints are black.

The marketing department in Sweden (and at Aimpoint INC in the USA) is always keeping an eye on technical developments and new trends. Aimpoint's successful collaborations with well-known gun manufacturers such as Glock (and previously with Brügger & Thomet or Blaser) also give reason to hope that there will continue to be exciting combinations of sights "made in Sweden" in the future.

The milestones of 50 years of Aimpoint history

- 1975: Aimpoint founded, the first Aimpoint Electronic sight introduced.

- 1980: First sight for military use, the Aimpointac for the Swedish Air Force.

- 1988: The Aimpoint 3000 is named "Optical Product of the Year" at the SHOT Show in Las Vegas.

- 1991: International recognition when US special forces are photographed with Aimpoint sights

- 1997: The US Army orders 80,000 sights (M68CCO), France orders 10,000 sights.

- 2002: Aimpoint Inc. is founded in the USA.

- 2003: Lennart Ljungfelt becomes CEO of Aimpoint.

- 2005: One million sights sold are exceeded.

- 2007: The US Army orders 565,000 Comp M4 sights – the largest order for optical military equipment

- 2010: Two million sights were sold.

- 2017: France orders 110,000 sights, total sales over three million.

- 2022: Four million sights sold.

- 2025: Lennart Ljungfelt steps down as CEO after 22 years; Per Lovatt becomes the new CEO.

Facts & figures: Turnover – 150 million euros in 2024. 460 employees worldwide. Head office in Malmö/Sweden.

Website: www.aimpoint.com