Fans of bullpup rifles should know the US company Desert Tech: under its former name of Desert Tactical Arms (DTA) it had made itself known as a manufacturer of very compact bullpup rifles. Although only active for 12 years, the factory based in the US state of Utah thus changed its name, but not its own claim: it's still about the "most accurate and compact rifle systems in the world".

The MDR rifle by Desert Tech

Behind the MDR acronym, Desert Tech hides the name "Micro Dynamic Rifle". And behind it is a modern short-stroke piston, multi caliber, bullpup design semi-auto rifle. Just 27.8”/ 706 mm long including flash-hider, the rifle measures significantly less than most coach shotguns used in Western shooting and less than some pistol carbines. For comparison: an Uzi submachine gun with the stock folded out comes to about 25.6”/ 650 mm, which is just one cigarette length shorter. Despite the small overall dimensions, the barrel of the gun is 16.1”/ 409 mm – the first indication of how clever Desert Tech paid attention to the packing size of this model. The currently available calibers and barrel twist rates are: .223 Remington / 5.56 Nato with Wylde chamber and 1:8" twist (203 mm), .300 Blackout with ultra-short with 1:6" twist (152 mm), and 1:10" twist (254 mm) in .308 Winchester. The gun comes basically in black and Flat Dark Earth (FDE). We were supplied an MDR in caliber .308 Winchester. So much for the basic technical description – now to the impression the rifle left immediately after unpacking and during the first safety and function check.

The testers saw an extremely compact bullpup-design rifle, with the magazine well behind the free-standing pistol grip, and a 3rd-generation Magpul PMag 20 in the magazine well. The first ambidextrous controls are to be found there: in the front, above the the trigger guard front there was a square button on the left and right side for releasing the magazine. At the front of the magazine well, in the middle, there was a push button for the same purpose. That means two controls for releasing the magazine, and both accessible from each side. The same also applies to the 2-position fire selector switches and to the charging handles on both sides, that are spring-loaded and fold forward out of the way when not in use. This means that the rifle is fully ambidextrous with regard to the controls.

The technology of the MDR in detail

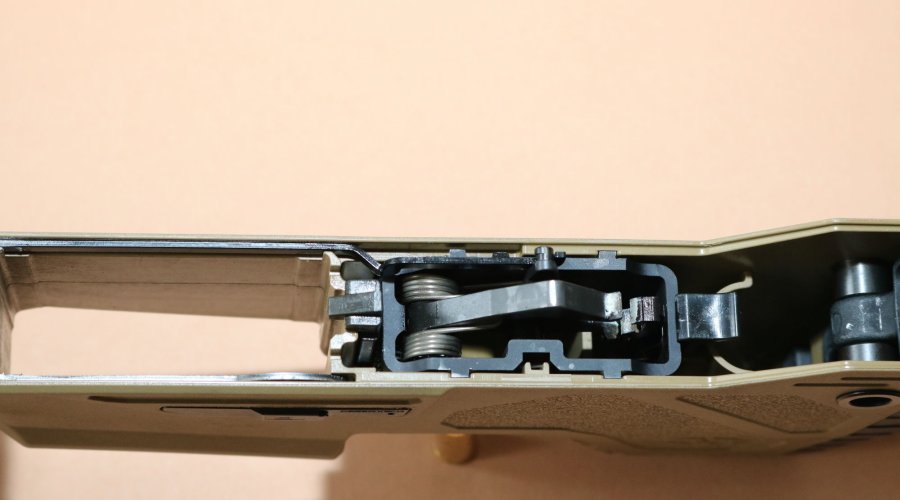

So far, so good and so easy. The question of how to look into the receiver gave more headache. When you pull the charging handle, you could feel and hear the usual mechanical movements inside, but nowhere did anything seem to move to the side or out of the way at all, so that an opening would appear – something through which the cartridge cases could fly out into the open and the eye could peer into the gun and thus check the chamber. It took a while before the solution was found even without reading the operating instructions: in the buttstock were two narrow rectangular steel inserts on either side, with a spring-loaded sliding button at the rear end. In other words: removable. And the insert on the right also had a small, downward opening dust cover.

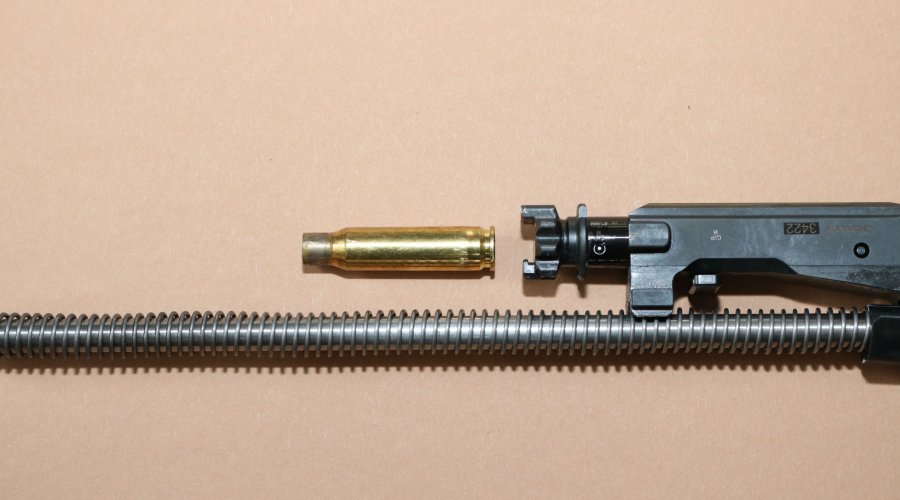

Underneath it was something that looked like the guide for a cartridge case. A razor-sharp conclusion: this dust cover sits at the front of the insert, which would mean that the MDR kicks the empty cases forward into the open, wouldn't it? To anticipate the test: exactly. And to peep inside? Very easy: if you pressed the slide on the element with the dust cover, you could remove it and then look inside the system. A closer look at this part, which is designated as Chute Panel/Assembly by the manufacturer, and its counterpart showed that the chute insert transports the case into the open via a guide. The ejector assembly pushes the case into the chute through a very complex, superbly manufactured toggle mechanism. The highlight is that these elements can be removed – without tools! – so that the ejector can be moved to the right or left as desired. Yes, and then you can reposition the dust cover above the ejection port: It can be opened upwards or downwards to your liking.

Barrel and handguard of the Desert Tech bullpup rifle

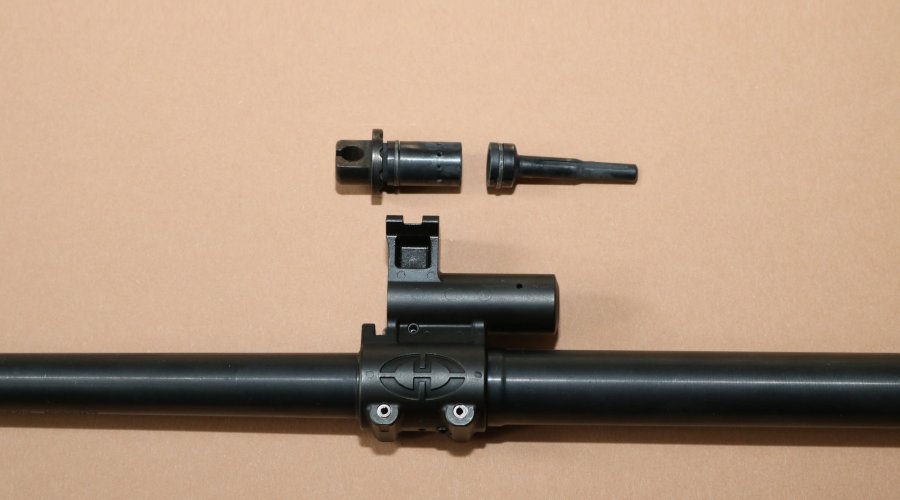

On the muzzle of the 16.1”/ 409 mm long barrel (5 grooves, right-hand 1:10" twist) is a 2.3”/ 59 mm long, very slim three-prong flash hider. Approximately in the middle of the barrel is the gas block, manufactured by MIM process, fixed with 2 taper pins. The gas valve has six holes from 0.45 to 1.4 mm - this marks production generation 3 of the Desert Tech MDR: Gen 1 had just 3 gas settings, Gen 2 has 6, but with different sizes than Gen 3. Which of the 6 settings fits best has to be worked out in view of the abundance of bullet weights and powder types. Generally, for suppressors choose a small hole or number. For normal operation, start with position 3. If there is a malfunction with the respective ammunition, the gas valve must be gradually rotated to a larger hole until the gun runs smoothly. This way the gas valve can be finely adjusted. This reduces the rifle wear: great. Piston o-ring seals are fitted to the gas valve and piston. The maximum piston travel is 0.45”/ 11.5 mm.

The fiberglass polyamide handguard weighs only 5.85 oz / 166 g and is very well made, plastic guides on both sides ensuring the connection to the receiver. Two retention screws keep it in place. A captured retention pin also secures the handguard. On top of the latter there is a 4.3”/ 110 mm long Picatinny rail. It's not possible to mount overbarrel suppressors with the hanguard of the test gun. But Desert Tech builds a bigger “suppressor” handguard that can cover it.

Details of the Desert Tech MDR system in .308

The lower receiver is made from fiberglass-reinforced injection molded polymer. The trigger group is split into two due to the bullpup design: the trigger assembly is pinned to the receiver, a trigger bar transmits the trigger movement over 10.8”/ 275 mm to the sear assembly. Several levers have to redirect the trigger force. This also explains the high trigger pull of about 30.5 N. The fire selector lever is located above the pistol grip, which is at a 75° angle. It directly locks the trigger bar when on safe. Three takedown pins connect to the upper receiver made from high-strength aluminum.

The barrel block is screwed to the upper middle section. The bolt carrier runs on the rails inside the upper. Underneath, there are two openings of 0.78” x 4.7” (20 x 120 mm) on both sides for the mentioned chute and ejector inserts. Due to the option of right/left case ejection, the ejector is located at the bottom center of the bolt head, now a little wider than in the older MDR versions. According to the manufacturer, the ejector should last for about 10,000 rounds when using brass cases. Above the bolt carrier, a non-adjustable cheek rest sits on the upper. And in front of it, the solid 8.8”/ 225 mm mounting rail can be seen, here without any forward inclination (it would be superfluous with the short MDR). All in all, the upper is superbly crafted and, due to the bullpup design, also very elaborate.

Assembling the Desert Tech semi-auto rifle

If you open the MDR case (it measures only 22.8” x 15.3” x 4.5”, or 58 x 39 x 11.5 cm), the MDR is broken down into 4 parts: barrel, magazine, handguard and receiver. To assemble it: lock the bolt in the rearward position. Insert the barrel from the front into the receiver as far as it will go. There should be a 1/16” (1.5mm) gap between the front edge of the upper receiver and the back edge of the gas block rail tower. Now rotate the rifle to the left side. Rotate the barrel lock screw by 180 degrees to the “Locked” position, and torque the barrel retention screws to 80 in / lb or 9 Nm. Then push out the handguard retention pin and slide the handguard over the barrel from the front. Press in the retention pin and tighten the two handguard retention screws. The required tool in the form of a T25 Torx and a 5 mm Allen key is included. With a little practice, the assembly takes only about a minute.

The bullpup self-loading rifle on the shooting range

Before the accuracy check, the testers mounted a Zeiss Victory V8 riflescope, with 2.8-20x magnification and a 56 mm lens. The scope features a very fine reticle 60 with fast reticle adjustment (ASV). The optic was fitted using an EraTac mount with adjustable inclination, which can be adjusted from 0 - 70 MOA with a gradation of 10 MOA each. Admittedly, with a length of only 27.9”/ 71 cm, setting up the rifle is unusual. The rifle scope is positioned relatively far forward, as the bolt runs in the rear stock of the Desert Tech MDR and thus the muzzle is also much further back. In short: very compact, which requires a change in the shooting position.

Despite the short barrel, we chose cartridges with bullet weights up to 190 grains, as the 1:10 twist rate should still stabilize the bullet safely. It worked perfectly: all bullets perforated the paper target in stable flight position. Thanks to the bullpup construction, the center of gravity of the gun is very far back. As a result, the bullet hits slightly higher than one is used to when firing with a conventional rifle. The testers were somewhat disappointed with the trigger. Its average resistance was 30.5 N – this corresponds to a trigger pull weight of a good 109.3 oz / 3100 g. And such a value is not exactly conducive to accuracy with a trigger travel of 0.19”/ 5 mm. A very good work was done by the three-prong flash hider, as it kept the flash to a minimum. We also liked the fact that all controls could be fully operated from right/left as mentioned, that there were 2 release possibilities for the magazine and that the 60-degree lever of the 2-position safety was not under the trigger finger. When the magazine is empty, you can press a lever behind the magazine well to release the rear-locked bolt. The fired cartridge cases fly out forward at an acute angle along the longitudinal axis of the gun, no further than 12” to 19” (30 to 50 cm). Typical for MDR, this does not happen when the bolt is pulled back, but only when the bolt spring is released. So, the case is still inside the gun when the bolt locks in the rear position. Ok, and malfunctions? After about 200 test shots: ...none!

Desert Tech MDR in .308 Winchester: wrap-up

The MDR hits the mark, is excellently manufactured and is very user-friendly: a technical delicacy, as it's fully ambidextrous and also with the highlight of the tool-free case ejection side change. Desert Tech also designed the MDR as a multi-caliber firearm for .223 Remington / 5.56 Nato, .300 BLK and .308 Winchester calibers. For the complex technology involved, the price of 3999 euro seems to be absolutely justified.

Text: Christopher Hocke and Matthias S. Recktenwald