Already in 2008 the guys at Albert Arms in Schweinfurt, Germany, started to develop a semi-automatic rifle in .338 Lapua Magnum (LM). In 2013 the factory completed the first prototypes of the Automatic Long Range Rifle (ALR) and presented them at the EnforceTac trade fair in Nuremberg. As a result, the German Federal Criminal Police Office (BKA) classified the ALR in .338 Lapua Magnum as a law enforcement/military restricted weapon. One year later the factory introduced the ALR in .300 Winchester Magnum for the civilian market. However, the BKA did not classify any semi-automatic gun in the .338 caliber family as a weapon of war, but explicitly only the one in the .338 LM caliber. This gave rise to the idea of developing a civilian ALR version in a different .338 caliber. Thus in 2017 Albert Arms started with the design of the ALR in .338 Norma Magnum (NM). This follows the trend, as the Norma Magnum versions in .300 and .338 are currently in vogue.

Comes the .338 Norma Magnum

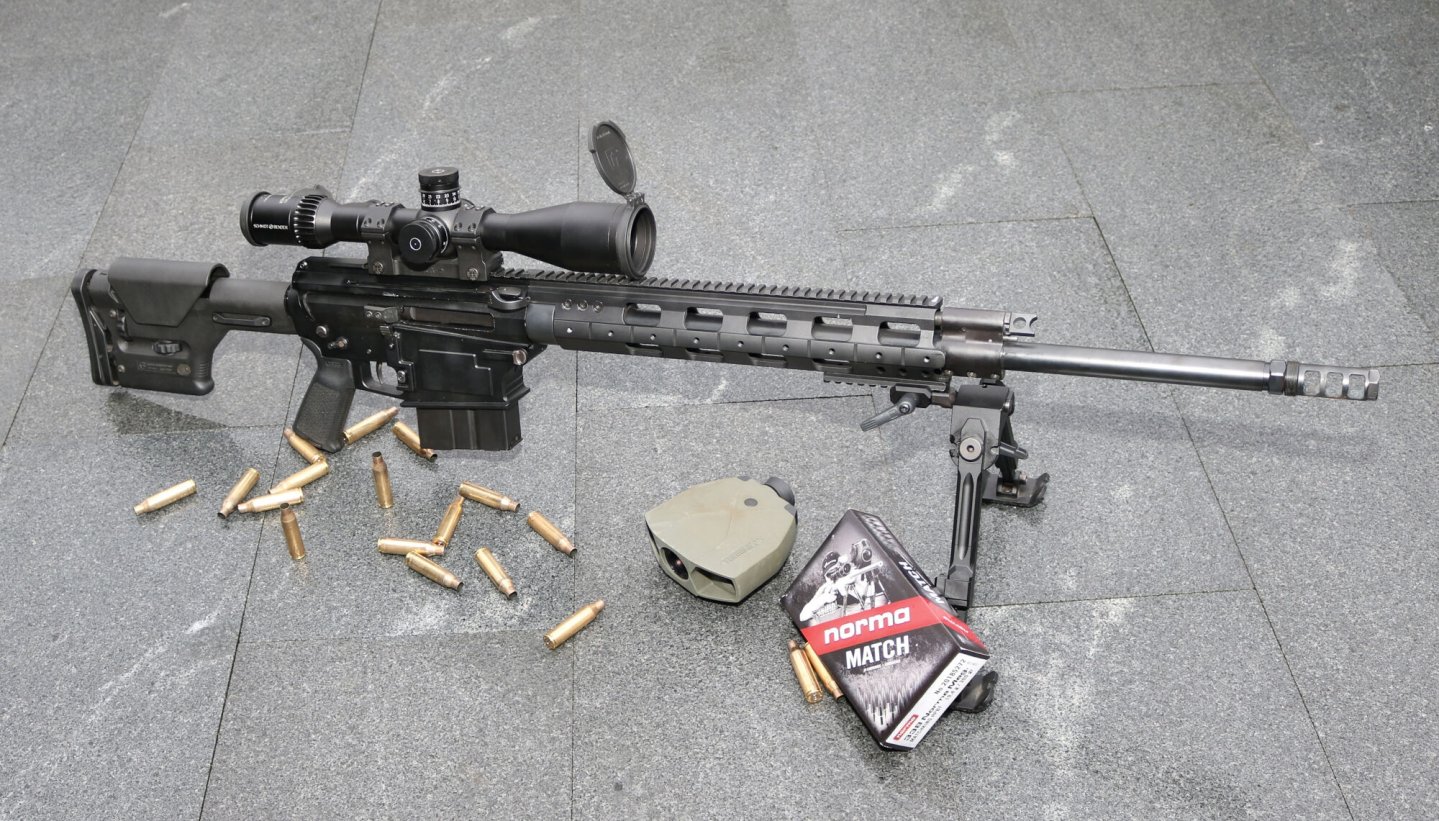

The answer to the question of what the .338 Norma Magnum offers is simple: compared to the .300 Winchester Magnum, it has about 25 to 30 percent more power. In contrast, the .338 Lapua Magnum and .338 Norma Magnum are about equal in terms of power. The first prototype of the ,338 Norma Magnum ALR was built in 2018. on April 9th, 2019, Albert Arms received the official permission for the civilian market by the BKA. all4shooters.com had the exclusive opportunity to test this extraordinary semi-automatic gun. For practical reasons, it makes sense to use an existing and widely used platform for a new design. Therefore, the ALR resembles at first sight a large AR-style rifle. A closer look reveals many similarities. But in terms of accuracy and details, the German rifle differs significantly from the AR system. However, this additional effort in terms of design and production technology has paid off, since with a grouping of only 1.96”/50 mm at 500 meters, the ALR 338 NM was quite impressive.

The ALR's lower receiver in .338 Norma Magnum

The ALR lower is made from high-strength aluminum 7075 alloy, which is milled from a solid billet. Stock and Magpul pistol grip follow AR standards. For the stock the ALR designer, master gunsmith Vitali Grauer, used a Magpul PRS. Its length can be adjusted in very fine 0.66 mm steps by a total of 1”/25 mm. The same fine adjustment is used for the cheek piece height. Maximum adjustment range is 0.78”/20 mm. Due to the standard AR attachment, other buttstocks and pistol grips can be mounted on the ALR according to customer requirements. All controls such as the magazine release button, bolt catch and safety lever are located on both sides of the lower, so that left-handed shooters can also operate the gun without having to re-position their arms. The safety lever describes a 90-degree turn between the safe and ready-to-fire positions. The lever is located above the trigger. If you miss the typical pictograms for the safety status in the photos of this article, you can rest assured: the test rifle was one of the first prototypes – the series production rifles will have the corresponding symbols, of course.

The trigger sits in a milled, completely removable aluminum assembly. The assembly is fixed with two pins into the lower receiver. In order to adjust the seat of the trigger assembly without play and thus significantly improve its characteristics, two grub screws additionally tighten the assembly. The trigger pull weight can be adjusted between 14.7 to 34.3 Newton, or 1500 to 3500 grams. According to Albert Arms' owner, Anton Albert, the construction of a suitable magazine was one of the biggest challenges. Due to the high cartridge weight of just under 1.76 oz/50 grams, the magazine spring must be appropriately strong in order to push the follower and the up to ten cartridges quickly enough upwards in the short time window during which the bolt head is located behind the cartridge bases. The solid sheet steel magazine already weighs 13.4 oz/380 grams when empty. By the way, the magazine floor plate can easily be opened with the groove of a .338 cartridge.

ALR: lower and upper connection

As with the AR, two captive takedown pins connect the two receivers of the ALR. Here the ALR already shows some technical refinements, which are usually not found in AR systems. The recoil impulse produced by the fired cartridge and the escaping propellant gases is transmitted from the upper to the lower via the takedown pins and then to the shooter's shoulder. For this reason there is a pressed and hardened steel bushing in the pin guide in the upper, and the takedown pin with a diameter of 7.9 mm is hardened too. The bushings therefore transmit the force to a larger area of the receiver. In addition, the steel bushing does not move, which sooner or later occurs with the AR-typical aluminum pin guides. This is why steel bushings should be standard for recoil-strong calibers. To eliminate the already minimal play between the smaller pin and the larger bushing, a clamping grub screw is located between the magazine well and the front pin guide.

The bolt of the ALR semi-automatic rifle

Even with the 20.77 oz/589 gram bolt assembly, there are various differences between the two systems. For reason of operational symmetry, the ALR has not the usual seven but eight locking lugs. Opposite the extractor there are two ejectors at 9 o'clock. This is due to the larger case mass and also increases ejection safety. The massive gas key is located behind the rotating bolt head. It transmits the movement of the gas piston to the bolt carrier. The gas key is not screwed to the bolt carrier in the typical AR manner, but is integral with it. There is also an extra firing pin safety – a lever on the hammer pushing a firing pin catch upwards. In order to prevent the exchange of parts between the ALRs classified as weapons of war in .338 LM and the civilian ALRs in .338 NM caliber, there are some differences between the bolt ring and the bolt guide.

The upper receiver of the Albert Arms rifle

The upper receiver is machined from solid billets, the material is again 7075 aluminum. For corrosion protection and improved wear resistance, as well as surface hardness, Albert Arms finishes all aluminum parts with a hard anodization. The charging handle, which can be operated from both sides, also requires two guide rods in order to allow axial movement of the bolt carrier during loading. The case deflector on the right side is screwed on, not an integral part of the receiver as is usually the case. Near the deflector, the AR-trained eye misses a detail. The ALR has no dust cover over the ejection port. Also, a forward assist is not available on the ALR. This clearly indicates that the ALR is a sports rifle.

At the rear of the upper there is a rotating cover. This only opens when the bolt carrier is pulled backwards by hand using the charging handle. A spring closes the cover automatically and thus protects the inside of the gun from dirt. During shooting and cycling, the cover always remains closed. In front of the cover there is a top rail carved out of the upper receiver. This rail is continuous with the handguard top rail. The free float handguard sits on a long cylindrical seat on the barrel nut. At the front bottom end of the handguard there is a Versa Pod adapter for bipod mounting.

The manufacturer uses Lothar Walther barrels. Depending on requirements, however, Heym or Merkel barrels can also be used. The 25.6”/650 mm barrel is polished and blued on the outside. There is a solid gas block in front of the handguard, fixed to the barrel jacket with three screws. The gas regulator has 3 different-sized bleed holes. The smallest one is intended for use with a silencer, the middle one for normal shooting and the large hole is to be used when the gun is very dirty. The respective regulator position is indicated by three differently sized white dots on the front of the top rail. With the indirect gas impingement system, the gas piston transfers the force generated by the gas pressure axially to the bolt carrier. The gas regulator features a labyrinth seal and thus seals against the gas block. A very slim three-chamber muzzle brake is fixed onto the muzzle. Despite a small baffle size, it works very effectively. The muzzle flash is diverted laterally by the three chamber openings. At the brake base there is an external thread for the mounting of a suppressor.

Shooting range visit with the .338 Norma Magnum semi-automatic rifle

Before the testers could indulge in the pleasure of testing, they went to procure ammunition components and loading data. Although the first cartridges of the .338 Norma Magnum were produced in 2008, the same year the development work leading to the ALR began, there is hardly any factory ammo available for this long-range cartridge. As of mid-2020, only two Norma factory loads were available, loaded with 300-grain match hollow-point bullets. Cases are available from Norma, Lapua, Hornady and Peterson. Reloaders can choose from a wide range of .338 bullets. There are also corresponding die sets available.

For testing, Albert Arms delivered the ALR 338 NM with a Schmidt & Bender 3-27x56 PMII scope mounted on a proven EraTac one-piece mount with 20 MOA forward tilt. The gas regulator was factory set in the middle position. This way the rifle works flawlessly. In the smallest position, however, the amount of gas bleed is too little – the ALR doesn't cycle. Therefore this position is intended for use with suppressors. The complex inner workings of a suppressor delay the pressure drop in the barrel, so that in this case even a small bleed hole can ensure cycling.

boss Anton Albert – as you can see, the rifle is also available sand-colored.

After the testers had shot the groupings with a total of 6 loads, they experimented with the gas regulator adjustment. With load 1 they fired a grouping circle of 8 shots at 500 meters. They shot the first two rounds with the smallest regulator setting, shots three to five with the middle one and the remaining three shots with the large setting. Despite this, the ALR impressed with a good grouping circle of 4.17”/106 mm, or 0.73 MOA. This value could even be more than halved with hand reload number 6: 1.96”/50 mm, or just 0.34 MOA groupings, were possible with the ALR 338 NM at 500 metres. This value is extraordinary for a semi-automatic rifle, and very good even for a precision bolt-action rifle. Two further points attracted very positive attention. Despite the thin muzzle brake, the gun recoil is mild. The brake diverts a large part of the burning gases to the sides. The second point should please reloaders, of whom there are probably quite a few in this caliber: After firing and ejection, the cartridge case shows only two slight markings on the head caused by the ejector pins. Case mouth and body came out unharmed.

Albert Arms ALR in .338 Norma Magnum: test conclusion

The ALR 338 NM semi-automatic long range rifle by Albert Arms offers excellent accuracy, very good workmanship and some technical solutions that not only improve accuracy but also increase the life span of the gun. Granted, 8990 euro is a lot of money. But if you compare the ALR with technically much simpler precision repeaters, for example from Haenel, Sako, Steyr or Accuracy, which are usually in the same price range or even above, the price is certainly justified in this case. On the part of the testers, the ALR 338 NM receives a clear recommendation to buy without reservation.

Text: Christopher Hocke and Matthias S. Recktenwald