Sturm, Ruger & Co. – since 1949 the name stands primarily for guns that have a lot to offer for little money. To put this into practice, rational production methods and a model policy that is not overrunning and designed for quantities are necessary. Due to this corporate philosophy, the establishment of an elite custom shop might not have been at the top of the priority list of the company with the red falcon logo. According to AFMER (Annual Firearms Manufacturing and Export Report), Ruger produced exactly 172,102 revolvers and 781,623 pistols in 2017. So it seems that the company has mastered production in large quantities. But what about small series from the young custom shop?

This is the Ruger Custom Shop

Everything started on October 12, 2018, because on this day the first SR 1911 Competition left the Master Shop. The signing of the sponsorship contract with 18-time NRA Bianchi Cup champion Doug Koenig may have set the ball rolling. The man from Pennsylvania, known as the world's best all-round shooter, won the 1990 IPSC World Championship and countless other prestigious titles. His experience, based on years of hard training and many victories, is certainly very helpful for the mass producer in the production of fine custom shop firearms. Because especially in the market segment of competition sport guns Ruger has always had a hard time. Hand-picked engineers and gunsmiths, together with Doug Koenig's consulting activities, are to create the promising basis for the success of the models from the young in-house custom shop. The current range consists of the Super GP 100 Competition revolver, the Doug Koenig SR 1911 Competition pistol and the 10/22 semi-automatic rimfire rifle in 3 versions.

Ruger SR 1911 Competition in 9mm Luger

Admittedly, one can be curious to see what a 1911 based on Doug Koenig's ideas might look like. In a nutshell: "Less spectacular, but with all the important things in mind". The slender stainless steel frame for single-stack magazines isn't muzzle-length. The black coating is obtained by a nitriding treatment, as is for the small parts and slide. On the front and back straps there is a fine 25 lpi (lines per inch) checkering. The G-10 grips with a non-aggressive surface texture and the falcon logo also ensure a good grip when firing. The transition area between the front strap and the underside of the trigger guard has been undercut as far as possible where the middle finger rests, just like the high grip beavertail, to allow the gun to sink deep into the hand. A double-sided safety is of course also part of the package and even has a little more contact surface on the right side.

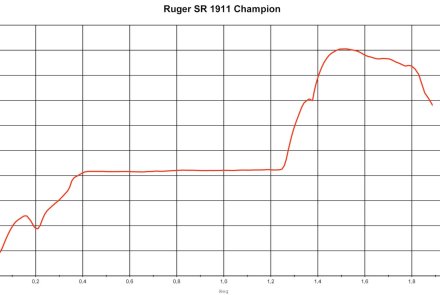

The sides of the slide are polished and feature rear and front cocking serrations for easy handling. The micrometer serrated rear sight is nicely coupled to the ramp front sight with green fiber optic insert. On this classically styled 1911 you will of course also find a barrel bushing. In contrast to the SR 1911 Target with "European" 1-10" twist, the SR 1911 Competition uses a barrel with longer 1-16" twist. This is intended to provide better accuracy even when using loads with lighter bullets. Under the barrel there is a long, one-piece spring guide rod. The trigger broke very cleanly at about 65 oz/1850 g. Certainly not a peak value in absolute terms and also due to American product liability, it is much better in reality. As clearly visible in the Triggerscan, about 30 oz/850 g are already used up over a travel of about 0.039”/1 mm. From there, it reaches quite fast the maximum value, so that only approximately 35 oz/1000 g have to be overcome for the shot release. Whether you prefer a straight or a concave-round trigger shoe is a question of personal preference. Supposedly, there are shooters who find the trigger pull weight on a straight trigger shoe to be lower.

The "low mass" hammer once developed by Evolution Gun Works (EGW) for Doug Koenig has lost a lot of mass due to 2 holes and a partial longitudinal cut. On the one hand, this should result in a quick ignition delay and less movement in the gun when firing. With our measured 5 ms ignition delay time it is certainly one of the faster representatives of external hammers. Whether the lower mass during striking off also means less movement when firing would be theoretically plausible, but not so easy to confirm or disprove. It goes without saying that the other trigger parts such as the trigger sear are made of high-quality steel and come from the renowned US manufacturer Cylinder & Slide Inc. A TechWell's magwell made of aluminum helps to quickly insert the 10-round magazines. With a width of just under 1.38”/35 mm, it complies with both the USPSA Single Stack and the IPSC Classic regulations. Two stainless steel magazines with plastic floor plates are included in the high-quality transport case. However, the latest addition to the Custom Shop is not quite so inexpensive. In Europe, the SR 1911 Competition costs just under 3000 euro (price may vary according to the country). The .45 Auto version, which also comes without a jet funnel, is available for 100 euros less.

Ruger Super GP 100 in .357 Magnum

Ruger never had an easy time competing with its revolvers against the dominance of Smith & Wesson. Factory competition models were rather rare, and the gunsmithing and tuning scene had also increasingly focused on Smith & Wesson. Now Ruger has re-shuffled the cards with the Super GP 100 Competition, at least for the in-house custom revolvers. The nickname "Super" comes from the massive, approximately 1.77”/45 mm wide cylinder, which can hold 8 of the powerful .357 Magnum cartridges – and of the softer .38 Special cartridges, of course. So the Super would have enough potential to compete in dynamic disciplines like the Steel Challenge. The cylinder is cut for clips so that it can be reloaded quickly. But if you have time to reload and the loading or unloading of clips is too annoying, you can of course also insert the cartridges into the cylinder in the conventional way. This is achieved by milling out only the area of the full moon clip on the front side of the cylinder. Side cylinder play was minimal, only longitudinally it could be shifted by about 0.0039”/0.1 mm. Therefore cylinder gap was between 0.0039” and 0.9978” (0.1-0.2 mm). This somewhat clouded the otherwise clean workmanship and will hopefully remain an isolated case.

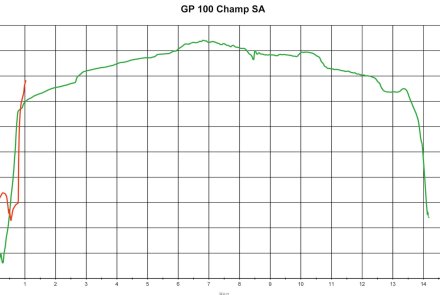

The cylinder yoke is also locked in the frame at the front, as seen in standard GP 100 models too. The ejector is generously sized so that even the long .357 Magnum cases are pushed far out of the cylinder. Ruger manufactures the frame using the well-known lost wax process. The more substantial dimensions of the investment casting that go along with this technique, however, still turn out quite appealing in this Super GP 100 Competition. Typical design features such as the one-piece, closed frame and the hammer's coil spring have remained. As usual, the complete trigger assembly can be removed in one piece with the trigger guard from the underside of the frame, for example for cleaning. Unfortunately, you will not find any tapped holes on the frame bridge for mounting an optic. Due to the trigger parts being reworked in the Custom Shop, the revolver features a smoother action. However, the measured values were still around 60 oz/1700 g in single action mode and 171 oz/4850 g in double action.

The Super GP 100 Competition was given a one-piece Houge wooden grip in the Jerry Miculek design in the Ruger Custom Shop, which at first glance appears smoother than it later turned out to be in practice. The chosen barrel length of 5.5"/140 mm seems ideal to us, as it is handy enough for dynamic disciplines and offers sufficient sight radius for accuracy static disciplines. For barrel production Ruger uses the technique of rotary swaging, better known as cold hammering. This technique is widely used in Europe, but hardly at all in the USA. Yet it allows for efficient barrel production, especially when compared to electrochemical processes. If you take a look inside, you will notice that rather unusual 8 lands and grooves wind their way through the barrel with a 1-16" twist. The micrometer rear sight on the top of the frame is complemented by a ramp front sight with a green fiber optic rod, which sits on the barrel jacket. The barrel jacket in turn has 6 distinctive cut-outs that become shorter in pairs towards the muzzle. The matte black PVD finish is more contemporary and resistant than a classic bluing. But here too, exclusivity has its price. The Ruger Super GP 100 Competition, for example, costs 1977 euros from the German Henke company, which was kind enough to provide us with the test guns. An 8-shot Smith & Wesson from the Performance Center, such as the M&P R8 or 327 TRR8, also costs 2069 euros. So it always remains something special to own an eight-shot revolver.

Technical data of the handguns from the Ruger Custom Shop

| Model: | Ruger SR 1911 Competition | Ruger Super GP 100 Competition |

| Price (prices

may vary according to the country): | 2959 euro | 1977 euro |

| Caliber: | 9mm Luger | .357 Magnum |

| Magazine/cylinder capacity: | 10 rounds | 8 rounds |

| Rear sight: | micrometer; 3.25 mm | micrometer; 3.6 mm |

| Front Sight: | 3.15 mm target with green fiber optic insert | 3.15 mm with green fiber optic rod insert |

| Sight Radius: | 185 mm | 191 mm |

| Safety: | double-sided

lever, grip safety | |

| Trigger/Pull Weight: | SA: 1819-1877 g, average

value 1849 g | DA:

4877-4919 g, average value: 4852 g; SA: 1689-1757 g, average value: 1731 g |

| Ignition Delay Time: | 5 ms | 11 ms (DA) |

| Total weight: | 1181 g | 1339 g |

| Dimensions (HxWxL): | 243x38x148 mm | 278x45x158 mm |

| Extras: | 2 reserve magazines, hard shell case | 3 full moon clips, hard shell case |

With the Ruger SR 1911 Competition and Super GP 100 Competition on the shooting range

We begun the test fire with the classic 1911. Here, 10 test loads, including 3 handloads, in the weight range from 115 to 147 grains were used. The best result was achieved by the Magtech 115 grains JHP, with 1.65”/42 mm. No malfunctions occurred during the test.

The next step was the Super GP 100 Competition. When comparing its shooting performance with classic six-shot revolvers, the 8-round guns have the disadvantage that 2 shots more have to be considered in the evaluation. In most cases this will mean a slightly larger group. Therefore, it is always advisable to use other "high-capacity" revolvers when comparing guns and loads. This time 10 loads, two in .38 Special and eight in .357 Magnum, with a bullet weight range of 125 to 180 grains were used. Despite the 1-16" twist, which is shorter than that of the Smith & Wesson revolvers, our .38 Special loads with 158-grain bullets did not deliver convincing accuracy. The .357 Magnum showed a better picture. First and foremost, our hand-loaded 180-grain H&N High-Speed bullet with 7.2 grains of Hodgdon Longshot, which made a 1.33”/34 mm group. With its low recoil and moderate muzzle/cylinder gap blast, this accurate load achieves the balancing act between .38 Special and robust .357 Magnum loads.

Ruger Custom Shop handguns: wrap-up

Ruger has certainly captured the trend of the time with the Custom Shop. The Super GP 100 Competition is perhaps an interesting alternative to the eight-shot revolvers from Smith & Wesson in Springfield. It is just a pity that a factory mounting option for a red dot sight is missing. The SR 1911 Competition impressed us with its excellent fit and practical top equipment, but unfortunately fell short of our expectations in terms of shooting performance. But with the right loads, it is still fully suitable for competition.

Further information about the SR 1911 Competition and Super GP 100 Competition from the Ruger Custom Shop can be found on the Ruger website.