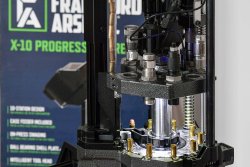

The X10 progressive ammunition reloading press made by Frankford Arsenal and available from STROBL.cz is a powerhouse, designed to reload thousands or even tens of thousands of rounds monthly of small arms ammunition easily and affordably.

We already talked about the X10. Assembling and setting up the X10 is not trivial, and requires lots of trial and error initially, especially if this impressive machine is your first multistation progressive press.

User groups and reload forums are the best source of information, from fellow reloaders that have ironed out the process and are enjoying the full advantages of this machine.

So I will not go over the actual setup in detail, noting instead the points that needed more attention and more time to tune correctly. Adjusting timing of the shell holder plate is trivial, as is the resizing/decapping die. The priming station is extremely easy to adjust and works flawlessly. The powder measure and dispenser was sort of a headache instead, as the micrometer adjustment is at its limit for the very small doses of propellant needed by 9mm – very fine powder (like the Vectan GM3 we used) tends to stick to the walls of the reservoir, possibly due to electrostatic effect – and I did wire to ground the whole machine, as it should be.

The bullet seater and auto feeding mechanism adjustment also was not as simple as I thought, it is very important to check the length of the bullet we want to reload (two feeders are included) and the feeder does tend to hang with non-plated lead bullets. So, use good quality FMJ or thick plated bullets for best results. I indeed ended up using Berry’s plated TC 124-gr bullets. The timing of the motorized rotors inside the case and bullet feeders also need to be adjusted for best results.

So, in short, after careful adjustment and trial runs, and once I developed the ideal 9mm pistol load using the reloading materials I have available – 4.3 grains of Vectan GM3 propellant with a Berry’s 124 grain TC plated bullet on a once fired Fiocchi case and using Fiocchi primers – I set out to start production.

Case preparation was kept to a minimum. I simply cleaned the lot of cases with a Frankford Arsenal Quick-N-EZ case tumbler kit, also available from STROBL.cz.

The very first 20 rounds loaded were set aside; I then loaded 1,000 rounds, and then the very last 20 rounds were also set aside. I loaded a total of 1,040 rounds, in two sessions of 510 rounds, separated by a week of pause. This was also to test the capacity of the press and all its components to retain all adjustments.

It is important to note that 1K rounds are basically nothing for this machine, and it takes about one hour to reload this amount. With a constant supply of components and propellant, the X10 is easily capable of reloading 6K of rounds per day! However, time and other constraints limited this test to 1K.

I have a dummy round hand built using the same components used for the production batch as a reference standard and as a production check. I used a digital caliper with 1/100mm accuracy for this. As a reference, the CIP standard calls for Overall length 29.69 mm/1.169”; however this is for FMJ round nose and I used a 124-gr TC, which ended up having an OAL of 29 mm with the prescribed seating depth.

Each of the first 20 rounds were measured and weighed, and 5 rounds randomly chosen were disassembled and the powder charge weighed. This leaves me 15 rounds each lot for the live fire tests.

| 1 | 2 | 3 | 4 | 5 |

OAL - mm | 29.03 | 29 | 29.02 | 29 | 29 |

Powder - grains | 4.3 | 4.3 | 4.2 | 4.3 | 4.2 |

The same fate also fell on the last 20, to try to find discrepancies; none were found, demonstrating that the Frankford Arsenal X10 progressive press is very consistent and also reliable in this, admittedly, short test.

| 1 | 2 | 3 | 4 | 5 |

OAL - mm | 29.01 | 28.98 | 28.99 | 29 | 29 |

Powder - grains | 4.2 | 4.2 | 4.3 | 4.3 | 4.2 |

To note, the amount of propellant loaded is obviously critical: I chose a Vectan powder that – beyond ballistic performance – is not so kind to volumetric measure/dispenser as it is quite sensitive to static/moisture due to particle size. So, this test was indeed critical.

As a reference, 15 carefully hand loaded rounds were painstakingly loaded measuring on a digital scale the powder and each round measured with a high accuracy digital caliper.

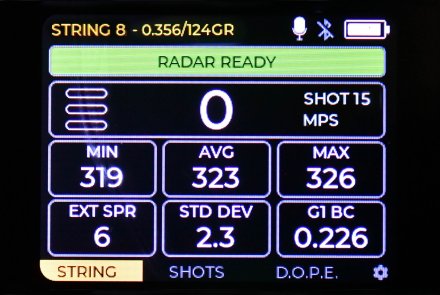

These rounds were then shot as our baseline the morning of our test at the range, speed measured with a Caldwell Velociradar chronograph, and the three groups of ten shots each also measured. This is my benchmark:

Speeds (control lot of 15 rounds):

| M/S |

Average | 323 |

SD | 2.3 |

MIN | 319 |

MAX | 326 |

Group sizes (5 rounds, shot at 15 m) in mm:

Group 1 | Group 2 | Group 3 |

38 | 27.5 | 27 |

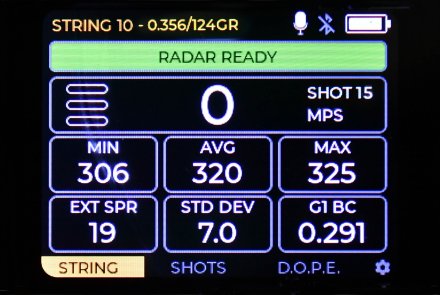

The very same morning, I shot the very first 15 rounds built under the same conditions and at the same distance from the same gun; and then, the last 15 rounds of ammunition loaded, again using the Caldwell Velociradar printing a total of six targets with three groups for each batch of ammo.

Speeds (initial lot of 15 rounds produced):

| M/S |

Average | 320 |

SD | 7.0 |

MIN | 306 |

MAX | 325 |

Group sizes (5 rounds, shot at 15 m) in mm:

Group 1 | Group 2 | Group 3 |

52 | 51 | 47 |

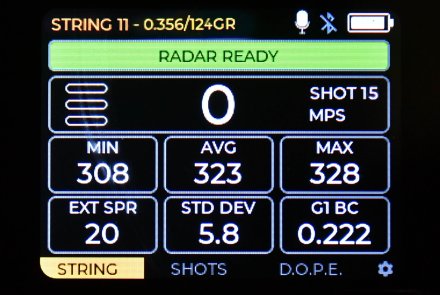

Speeds (final lot of 15 rounds produced):

| M/S |

Average | 323 |

SD | 5.8 |

MIN | 308 |

MAX | 328 |

Group sizes (5 rounds, shot at 15 m) in mm:

Group1 | Group2 | Group3 |

42.8 | 35.8 | 43 |

The results are impressive, even with such a low sample size. Basically, all ammo performed the same, with decent SD and the same group size – of course, limited by my shooting ability!

I used a CZ 75 SP01 Shadow with Match barrel for the accuracy tests and a Beretta 92FS plus a Glock 17 Gen3 for the reliability and function tests. Basically, a good chunk of the 1000 rounds I’ve loaded were burned up for this. I did not include those results in the test but nonetheless had a lot of fun shooting in the last couple weekends at the range!

Wrapping up

Well, what can I say – the X10 delivers, and it’s great. Accuracy is excellent, and it’s a very reliable beast in our testing. I’d love to test it for rifle ammunition as well, and I may just do that – I also shoot .223 and it would be very interesting to try it out, especially now that a bullet collator and feeder is available for rifle bullets as well; alternative bullet feeders by Armanov now are also now available on STROBL.cz website.

My impressions are positive. I cannot say about its really long term reliability – and I mean years, as in decades! – but it’s an overbuilt, over-engineered machine that seems very cleverly designed, that had no hiccup of any kind in all my reloading and that, again, delivers on its promises. In good conscience, I must recommend it if you’re looking for an affordable ten-station progressive press, able to load anything under the sun, up to and including .308 size brass.

Products mentioned in the article:

https://www.strobl.cz/en/frankford-arsenal-x-10-progressive-press-with-case-feeder p11877: 1,605.84 Euro

https://www.strobl.cz/en/frankford-arsenal-9mm-x-10-bullet-feeder-conversion-kit p12328: 245.92 Euro

https://www.strobl.cz/en/frankford-arsenal-x-10-bullet-feeder-collator p12327: 210.80 Euro

https://www.strobl.cz/en/9mm-luger-lyman-pro-die-pack p12552: 366.50 Euro

Click here for more information on the topics: