Mil-Spec, i.e. "built to military specifications" – magical words that have since been used to describe, in ads and marketing hype, any commercial product that is claimed to be better, faster, stronger than average.

No product category is exempt from it. Cars, sports and outdoors gear, tools, even high-end audio Hi-Fi components in the past...

Firearms are no exception – actually the opposite: every brand has at least one if not several products, from hunting, sports or personal defense fields, which claim finishes, materials or passing endurance tests that are according to this or that military standard. But beyond all this, among shooters and fans of AR15 based firearms, “Mil-Spec” has a completely different meaning from all the marketing hype that afflicts advertisements.

So, what do we mean when we say that a firearm based on the AR-15 platform is "Mil-Spec"?

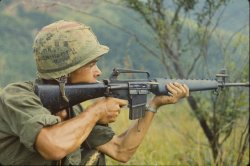

First, let us get out of the way that no civilian black rifle can ever be Mil-Spec. An official service weapon is built according to a broad set of binding and stringent military standards, which beyond the simple design and blueprints of the weapon (the so-called TDP, or Technical Data Package), firmly guides every step and aspect of the construction, the testing protocols, the logistic and administrative management, then, once delivered to the assigned unit, the weapon’s maintenance, use and its end of life cycle.

Even only considering the weapon by itself, the configuration is a mandatory part of the specifications and if even one part is out of spec, the entire weapon is. Only the M16 rifle and M4 carbine in their officially adopted variants are really Mil-Spec.

On the other hand, experts and fans of the AR-15 platform have been, and still do, freely use the term "Mil-Spec" explicitly in regard to civilian semi-automatic firearms. What gives?

In short, what they mean by a firearm based on the AR-15 platform being Mil-Spec, is that said firearm is compliant to a set of established industry standards that makes it compatible with all the accessories, spares, replacement parts, and even specific feature sets, that follow this definition. For example, if I wanted to replace the bolt or the fire control group of my “Mil-Spec” Black Rifle, I know that a Mil-Spec compliant part will work perfectly.

Not only that: the above mentioned industry standards, that are collectively called Mil-Spec because they have been borrowed from the original Military Standards that applied to the M16/M4, also include for each part the minimum levels of quality and performance. Therefore, a Mil-Spec built part will also guarantee a level of quality and durability that could widely exceed the performance of a commercial, non Mil-Spec part... or, not. Makes sense?

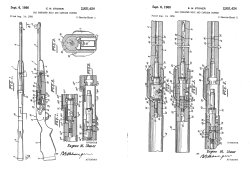

We need to go back a bit for this

Colt purchased the AR-15 design, trademark and patent from ArmaLite in 1959 (the gun was designed as a selective fire military weapon) and, due to its initially low military sales, thought to offer it on the commercial market in a semi-automatic only version. As early as January 1964, a civilian-legal version approved by the US Treasury Department was offered for sale as the Colt AR-15 Sporter. With this rifle, Colt introduced a whole series of modifications to the design to make it difficult to convert the civilian semiauto firearm into a machinegun.

The following list sums up all the changes that have piled up in time since the first Colt R6000 Sporter introduction and subsequently evolved in the following 55 years, changes that had their absolute peak from the mid-90s until 2004 with Clinton's Assault Weapon Ban, and which since then have surprisingly gradually relaxed, to the point that many Colt AR rifles of the last decade so are mostly aligned to the Mil-Spec industry standard.

Lower Receiver: the Pivot Pin is replaced by a two-part screw of larger diameter and offset in respect to the original pin placement, so it is impossible to drop-in a military upper receiver; the selector lever stops are milled off; a steel block is permanently installed in the rear of the receiver that prevents the use of a military BCG and Auto Sear Assembly (from late 1989 to mid 90s); portion of the lower receiver between the FCG and take down pin slot left solid, again to prevent installation of an Auto Sear Assembly.

Fire control group and safety: all parts modified or completely redesigned, with larger diameter pins (since 1991 to the end of 2009).

Upper receiver: lack of a Sear Relief Cut in front of the Take Down pin lug to allow correct operation of the Auto Sear Assembly; larger diameter and offset Pivot Pin hole in the front lug.

Bolt Carrier Group: lower part of the rear of the carrier machined in various ways, from removal of just a centimeter or so of material all the way to complete removal of the lower portion, to restrict engagement of the Auto Sear; machining of the firing pin area to intercept an out of battery hammer fall (so called “slam-fire”).

Barrel: chambered for .223 Remington instead of 5.56 NATO, different rifling pitch; in the case of the M4, a 16" barrel instead of 14.5" (to comply with NFA rules); from 1994 until a few years ago, no threading in the muzzle, except for LE models; bayonet lug on the FSB is removed.

Not all of these changes are present in a single firearm at any given time.

The "Mil Spec" definition concerning the AR platform can be traced back to the years after the expiration of the Stoner and Colt patents in 1977. Since then, non-Colt firearms based on the general AR-15 design began to appear on the US market. By the end of 1977, the AR-15 was not such a popular or widespread gun: the total number of Colt Sporters sold – the only AR rifle available at the time – from '64 to '77 is exactly 79,433 units (worldwide!). Surprisingly, it is competition that will make Colt's AR-15 rifles hugely popular: beginning in 1979, Colt will sell exponentially more Sporter rifles than it had ever before.

Between 1977 and 1979, along with a limited availability of original military parts (mostly used, surplus parts and some "overrun" spares from Colt, Hydra-Matic, Harrington-Richards and other military contractors), a large number of copied parts were offered by small independent manufacturers (Sarco, Gunsmoke Enterprises, Nesard ...). Compatibility between the various parts was at the very least uncertain, as was the quality, which varied from mediocre to downright gruesome. It must be noted that no actual technical information really existed at that time, and that reverse engineering and a good amount of guesswork was basically the only way to recreate these parts.

At the same time, other manufacturers introduced on the market the only part that, until then, really was unobtainable, and which would allow building an AR-15 gun: a semi-auto only lower receiver, which under US law, constitutes the firearm. Non-Colt AR-15’s on the market in this period were basically all "kit guns" and quality was iffy at best. It was companies such as SGW (which will later become Olympic), Sendra, Quality Parts Company (later Bushmaster) that supplied parts and kits, and then, starting 1980, complete firearms. "AR-15" is a registered trademark of Colt even today, so product names were quite evocative, for example Bushmaster with its XM15.

It has to be noted that all non-Colt AR-15’s manufactured since then are not based on Colt's civilian models, and therefore do not follow the Colt pattern of internal and functional modifications for differentiation from military models. Rather, they will use the "military" pattern as far as possible, and as far as allowed by the BATF (Bureau of Alcohol, Tobacco and Firearms), making it possible to use many military parts, such as complete upper receivers, and in other cases, military parts permanently modified to make them capable of semi-auto fire only.

For example, the hammer, with its rear Auto Sear engagement hook milled off, and the Bolt Carrier Group, with its rear-lower part machined off for the same reason.

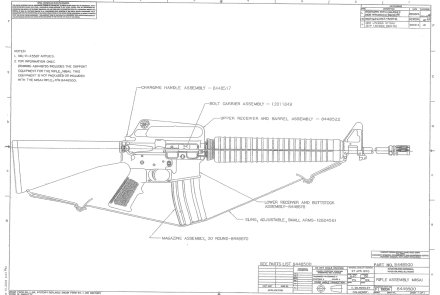

But in the early 1980’s, thanks to the way how US military spare parts and accessories tenders work, much of the more generic specs and information was disclosed, and even from time to time portions of the M16 TDP – which was and still is Colt’s intellectual property – were delivered to an uncountable number of manufacturers. Said manufacturers lost no time in unofficially redrawing drafts and blueprints for internal use of the individual parts over and over again. A myriad of companies, close to military circles, had the opportunity to view and take advantage of Colt's M16 TDP. However, it’s in August of 1996 that the entire Colt M4 TDP was released to over 20 companies for the SOPMOD accessories competition. We are not going to discuss the “M4 Addendum” or FN involvement here. However, the information is out there.

In any case, the early 90s see the huge popularity of the Black Rifle, with over one and a half million firearms sold (590,000 of these are Colt AR-15’s), and the information acquired from the M16 TDP has been silently passed from manufacturer to manufacturer, with the result that all the parts produced by these companies were then "mysteriously" perfectly compatible with each other. Lists were created of firearms and accessories that "follow the specs", which are therefore known as "Mil-Spec".

Groups of shooters and fans of the platform compile a list of what the "Mil-Spec" specifications actually are, in a sense as a desiderata set of requirements – you can find a brief summary of it at the end of this article. In 1994, the infamous Assault Weapon Ban explodes, which helped sell more "assault weapons" than anything else ever before – especially at its end in 2005, and today no one knows for sure how many AR rifles are currently privately owned in the United States, with estimates going from at least 10 to over 15 million units. Millions more are scattered around the world. Black Rifles have since been independently built in many other countries, including Europe.

Today, manufacturers of accessories, spare parts and complete firearms that declare "Mil-Spec" compliance, do not claim so for advertising purposes, but simply to disclose the compatibility of their products.

To wrap up, possessing a Black Rifle that has as many "Mil-Spec" features as possible does not automatically mean that we own a better product, but simply that it’s more compatible. There are many guns that we can define as "spin-offs" of the AR-15 platform, but which deviate significantly from it, such as the HK MR223, SIG Sauer 516 and MCX, POF-Usa piston guns, Ruger’s SR-556... Definitely, being proprietary doesn’t mean being of inferior quality, indeed.

List of "Mil-Spec" features for the semi-auto AR-15 and M4

| Bolt: | machined

from steel stock (C158 is specified, or better), shot peened, heat treated and High

Pressure Tested (HPT) (in this regard, it’s important to note that the US does

not have a National Proof House and that it’s not mandatory to have a HP test

as it is in EU) and subsequently Magnet Particle inspected (MPI); Manganese Phosphate Coating (AKA

Parkerization); 5-coil spring extractor, black insert and O-ring. |

| Bolt

Carrier Group: | machined

from steel stock (8620 is specified, or better, i.e. 9310), heat treated, hard

chrome plating in the bolt seat and Gas Key, Manganese

Phosphate Coating, staked Gas Key screw heads. |

| Barrel: | MIL B-11595 CMV steel is specified (similar to 4150, with Vanadium added), Fully Manganese Phosphate Coated before FSB assembly, hard chromed chamber and bore, 5.56, High Pressure Tested (HPT) and Magnet Particle inspected (MPI), with 1/2×28” threaded muzzle for flash hider; the Front Sight Base (FSB) must be marked "F" in conjunction with flat-top uppers and feature a bayonet lug. |

| Upper receiver (all types): | machined from a 7075-T6 alloy forging and hard anodized according to MIL-A-8625E Type III in matte black or matte gray, and internal finished with Solid Lubricant Film according to MIL-L-8937D; standard Pivot and Take down pin lugs; M4 feed ramp cuts for the Barrel Extension; Sear Relief cut next to the Take Down pin lug. |

| Lower

receiver: | machined from a 7075-T6 alloy forging and hard anodized according to MIL-A-8625E Type III in matte black or matte gray, standard FCG pins diameter of .154 ". No modification that blocks the use of M16 BCG; Standard Pivot and Take down captured pins. The Lower Receiver Extension, or Buffer Tube, must also be machined from 7075-T6 alloy, feature 5 stock positions, bleed holes for water evacuation, and a diameter of 1.14 ". For comparison, a Commercial Buffer Tube has a diameter of 1.17 ", is not entirely machined, and generally has an inclined end. The Buffer Tube must be secured to the Lower Receiver with a staked Castle Nut. |