The conversion of British muzzleloaders to breechloaders according to the Snider system: a topic that is usually only summarised in the specialist literature. This was an important step in the transition from muzzle-loaders to rifles using centerfire cartridges. After Prussia, Great Britain was the second country to consistently use breechloaders in its military. Unlike other adapted muzzleloaders, British Snider rifles can easily be made to "speak" again. How to do this, what modifications were made during the changeover and where Snider rifles were used is the subject of this article:

Around 1860, the British military had the Enfield rifle Pattern 1853 (P/53) and its variants (Short Rifle, various carbines), which fired accurately – perhaps the best military muzzleloaders ever made. However, after evaluating the German-Danish War (1864) and the first battles of the US Civil War (1861-65), the War Office realised that the future belonged to the breechloader. So on 25 August 1864, it announced a competition to convert muzzleloaders into breechloaders. The winner was to receive a £5,000 prize, but only under two conditions:

- The conversion could cost a maximum of one pound sterling per rifle.

- The breechloader had to shoot at least as accurately as a muzzle-loading Enfield rifle.

There were 50 proposals, eight of which were shortlisted. The first test phase began in January 1865, followed by a second in March 1865. Jacob Snider's design ultimately prevailed despite its poorer accuracy. This was because Colonel Edward Mounier Boxer, who was responsible for developing ammunition for the British army, lobbied heavily in favour of it and promised a more accurate cartridge. The French gunsmith François Schneider also played a part in Snider's design, and it was also developed by Colonel W. M.H. Dixon, the head of the rifle factory in Enfield. The result was a breechloader with a side-swinging breech block. While Snider wanted to cut open the top of the barrel and mount the breech block on it, Dixon introduced a component known as a "shoe" that contained the entire block. For the conversion, the tail screw was removed from the disassembled barrel, a piece about 2.5 inches long was cut off the rear of the latter and the end of the barrel bore was slightly widened to form a chamber. A thread was cut on the outside and the barrel was screwed into the aforementioned shoe. The Snider breech block was officially adopted on 18 September 1866. All British military rifles in service were now converted. By the end of April 1867, there were already around 136,000 converted pieces. When the muzzle-loading rifles were exhausted by the end of 1868, new rifles with the Snider breech block were produced.

In terms of armament, the soldiers of the line regiments carried the long Enfield rifle with a spike bayonet, while the sergeants of the line regiments and the rifle regiments carried the short rifle with a sword bayonet. The first major use of the Sniders was in 1868 during the British punitive expedition to Ethiopia on 13 April 1868 at the Battle of Magdala, the last in 1873/74 during the Third Ashanti War. Although only intended as a temporary measure, the Army used the rifles for almost eight years. After that, they were used by reserve police and colonial troops. It was not until after 1900 that the Army finally phased them out. Surplus wholesalers such as the Hamburg-based Adolf Frank (ALFA) continued to sell the Sniders until the First World War.

Snider modification variants

The conversion was carried out systematically. The military analysed the first modifications to identify weaknesses. These were then addressed in the next batch. A Roman numeral and one or at most two stars were usually stamped on the front of the receiver. These stamps labelled the respective version (Mark, abbreviated Mk.) of the conversion. Changes introduced in the previous version were retained in the next conversion stage:

- Mk. I: The rifle is designed for a cartridge with a rounded rim.

- Mk. I*: Based on rifles MK.I rifles, the chamber was adapted to cases with a squared rim.

- Mk. II*: Like Mk I*. However, the rifle was already built this way and not subsequently modified.

- Mk. II**: Five changes, including the shape of the extractor and breech block.

- Mk. III: Rifles with the revised breech from 1869 were completely new. The most important differences compared to the Mk. II** are the breech and the steel barrels.

If one of these stamps is missing, it is certainly a newly manufactured Mk. III-type weapon. If the breech block bears the inscription "Sniders Patent", it is a British commercially manufactured component.

Block variants Mk. I to Mk. II**: A spring-loaded pin in the back of the housing held the solid block on the outside right of the shoe.

Block variant Mk. III: Because the breech block occasionally opened when firing, it was revised in 1868. It was fitted with a solid latch that engaged in a recess in the rear wall of the receiver when locked, thus holding the block securely in place. The latch could be released by pressing a lever.

Non-British Snider rifles

The Netherlands and Denmark used a modified Snider system for muzzle-loading conversions. Portugal purchased a large quantity of Snider rifles and cartridges from Great Britain from 1873 onwards, but also manufactured its own, such as the Model 1875 artillery carbines, whose barrels came from Belgium and the systems from England. Serbia, Montenegro, Turkey and Egypt also used them. The rifles from Nepal are something special. Due to the political tensions between India, Tibet and China, British rifles could not be transported through India to the Himalayan country. Sniders were therefore handmade locally. They were in service with the Nepalese army. They were then stored in the Kathmandu armoury... and forgotten. This store was rediscovered at the turn of the millennium. Civilian British gunsmiths also modified muzzleloaders and made new Sniders for hunting and sport shooting. These pieces were also available in calibers other than the military .577 snider.

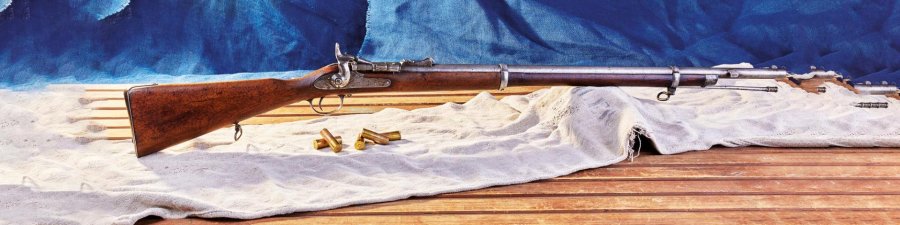

The Snider rifle presented here...

...is a Mk. II* and thus a converted piece. It was made in 1861 in the Enfield rifle factory as a short rifle and was converted to a breechloader between 18 September 1866 and 1 January 1868. Often rough handling left marks on the barrel and stock. The Short Rifle can easily be confused with the P58 Naval Rifle. However, it differs from it in its iron sights and the position of the rear sling swivel. The "Pattern 56 Yataghan Bayonet", a long sword bayonet, belongs to the Short Rifle. Although it would also fit on the P58 Naval Rifle, it does not belong to it, as the Navy used the "Pattern 1859 Naval Cutlass Bayonet" for its rifles.

The .577 Snider cartridge

The .577 Snider was developed on the basis of designs by Clement Pottet and François Schneider by Colonel Edward M. Boxer. He received two British patents for the primer variant (No. 137, 15 January 1866; No. 2653, 13 October 1866) and one in the USA (No. 91,818 from 1869). The Boxer cartridge case consisted of three parts:

- Body made of rolled brass foil with a layer of paper impregnated with linseed or tar oil for sealing

- Brass cup base

- Extraction disc made of brass, from cartridge Pattern IV made of lacquered iron

The iron disc was riveted to the base, with the primer pocket serving as the rivet. The body was inserted into the base, compressed at the bottom, and secured with an inserted cardboard ring. A hole was drilled in the top of the primer pocket so that the flame from the anvil-tipped percussion cap could reach the powder charge. While this design appears cumbersome, cardboard or plastic shotgun shells based on a similar principle are still used today. Solid brass cases only came after the end of the Snider service life. In Great Britain, the cartridge was loaded with 70 grains (4.54 grams) of coarse-grained military powder of the R.F.G. variety. During manufacture, the grains should pass through a 12-mesh sieve, but not through a 20-mesh sieve. The bullet was a hollow-base version; caliber: .573 to .574". A wad sat over the powder and under the bullet, a plug sealed the hollow base of the bullet. The cartridge was revised nine times between August 1866 and August 1871. The first versions were called "Pattern I" to "Pattern V", after which the changes were called "Mark VI" to "Mark IX". The main changes were the introduction of the iron extraction disc and reductions in bullet length and mass: the overall cartridge length shrank from 1.12 to 1.04 inches and the bullet weight fell from 525 to 480 grains. Boxer ultimately created a cartridge that shot equally well from the P53 rifle with a 1:78" twist rate and from the Short Rifle with a 1:48" twist rate. However, the Snider cartridge always remained sensitive to lateral drift.

Loading and unloading the Snider rifle

To load, put the hammer to half cock and rotate the breech block sideways (on Mk. IIIs, press the lever on the locking latch beforehand). Insert the cartridge, push it into the chamber with your thumb and close the breech. Once the hammer is in the cocking position, the gun is ready to fire. To unload or eject the fired case, return the hammer to half notch and open the breech. Now move the extractor to the rear as far as it will go. Then pull the case completely out of the stock with your fingers before tilting the weapon to the right to eject it. Sniders proved themselves in battle, were reliable and precise. They could fire approximately 6 to 10 rounds per minute. Of course, loading and unloading took a lot of time. This was due to the manually operated extractor and the lack of an ejector.

The Snider rifles today

Snider rifles can occasionally be found in classified adverts. Anyone looking for such an old-timer for shooting should not only pay attention to the condition of the stock and the like, but above all to a complete breech block and a good barrel, because long service and rough handling have unfortunately not been without consequences on (and in) many of these weapons.