The family name Walther, always spelt with a "th", has a very special ring to it in the international world of firearms. There can be no doubt that this is primarily due to Carl Wilhelm Freund Walther. Born in 1858 in Zella-St. Blasii in Thuringia, Germany, this gunsmith already came from a family with a tradition of gunmaking, and so in 1886, at the age of just 28, he founded his own small company, which a century later would be known worldwide for its excellent sport shooting, hunting and self-defense firearms.

Carl Walther and his wife Minna raised five sons: Fritz, Georg, Wilhelm, Erich and Lothar, the youngest, who will also be the subject of this story. While Fritz Walther, the eldest son, took over the company after the sudden death of the company founder in 1915 and gradually converted it to the production of the increasingly popular self-loading pistols, Lothar, born on 3 May 1899, initially learned the toolmaker's trade in his parents' business. During the First World War, he served as an aircraft mechanic at an Imperial Air Force hangar. He then went on to study engineering at the technical centers in Hildburghausen and Frankenhausen, which would be the equivalent to a university of applied sciences today.

ntWhen he returned to his parents' business, Lothar was able to further deepen his technical knowledge and practical skills. However, there was still no room for the youngest son to take on a responsible position in the family business. On the initiative of his older brothers, he was therefore paid his share of the inheritance. The modest settlement awarded to him lost all of its value as a result of inflation. In 1920, he therefore decided to spend an extended period overseas.

The journey went from Hamburg via La Coruna in Spain, from there by steamship Danzig to Buenos Aires, in Argentina. There he worked as an engine mechanic in a vehicle repair workshop. The next stop on this adventurous journey was the oil fields of South America. In Comodore Rivadavia on the Gulf of San Jorge, he learnt about the harsh world of oil extraction and processing.

Lothar Walther founded his company in the former family home of the Carl Walther family

Lothar Walther returned to his native Germany in 1921 with many new experiences and impressions from this world, which was so foreign at the time. He wanted to combine his knowledge of mechanics with his previous training in gunmaking, and so on 1 May 1925 he took the plunge into self-employment. In the meantime, his family's increasingly successful company had moved into a new factory building. He founded the company "LOTHAR WALTHER Werkzeug- und Waffenfabrik" ("Tool and Weapons Factory") in his parents' old house and the neighbouring, unused workshop space. Right from the start, he focussed on the manufacture of barrels, as their precision and durability are essential elements of a good firearm. He also knew this from his own experience: as a successful sports shooter with the service pistol and the Olympic rapid-fire pistol, he was a member of the German national pistol team for a long time in the 1930s and 1940s. He won German individual and team championships, the bronze medal at the 1927 World Championships and took part in many international competitions. This practical knowledge naturally also had an impact on his expertise in gun and toolmaking.

He was closely supported in the company by his wife Gerda (née Triebel), whom he married in 1926 and with whom he was to raise five children. Over many years, Lothar Walther developed the so-called non-cutting drawn process, i.e. the button rifling, a technique that was clearly superior to the conventional cutting methods used until then. In this innovative process, the barrel grooves and lands are cold-formed in a single operation using a tool (the "button") pulled through a drilled barrel without removing any material. This results in a significantly higher strength in the particularly stressed barrel bore than in the original material, while the strength of the rest of the barrel remains unchanged.

This knowledge earned Lothar Walther's barrels, which were soon supplied to numerous gun manufacturers, a very good reputation, but one that was not without danger. The turmoil of the Second World War and politics also intervened here. Shortly before the end of the war, Lothar Walther was forced by a Wehrmacht decree to disclose his barrel manufacturing technology, which had previously been considered a trade secret, to other manufacturers. However, the company's time in Zella-Mehlis was already over by the end of the war. As with many other Thuringian arms manufacturers, including the brother company Carl Walther, the American occupying forces ensured that they were quickly relocated to an area under their control: Thuringia was to fall under Soviet control, and the Americans wanted to secure the gun manufacturing expertise located here for themselves.

On June 29, 1945, the journey took over 15 hours through war-ravaged Germany to Heidenheim an der Brenz in Württemberg, using simple trucks and carrying only a few belongings. From the reception camp set up there, Lothar and Gerda Walther's family was transferred a few days later to Ochsenberg, now part of Königsbronn, and housed in an empty farmhouse.

Like other manufacturers, Lothar Walther's family was relocated to the American occupation zone in 1945

There, a new chapter of his life began, though initially, of course, without any connection to firearms. An old lathe with a reduction gear, a field forge for forging the necessary turning tools, and a simple grinding block: that was all the now fifty-year-old had at his disposal for his second fresh start. Since the occupying powers prohibited gun production until the 1950s, Lothar Walther initially manufactured bolt-action devices and accepted every available order for the production of mechanical components. When air rifles, which had previously been dismissed as mere toys, were finally permitted again (from 1950 with smoothbore barrels and from 1953 with rifled barrels), the barrel specialist began manufacturing barrels for these emerging sporting and recreational guns – thus laying the foundation for the later international success of his company.

Barrels for precision air rifles and customized rifles in particular made a name for themselves worldwide – and the next generation got on board

Lothar Walther air rifle barrels are now considered the gold standard worldwide when it comes to maximum precision, because the smaller calibre of PCP air rifles alone is not enough to achieve the tightest shot groups. This requires more expertise. Abroad, higher muzzle energies than those limited to 7.5 joules in Germany are permitted. The British market in particular, where PCP air and spring-loaded rifles are used for both hunting and "field target" sport shooting, benefited in the following decades from the imported "LW barrels" from Königsbronn, where the company had already moved at the end of 1949 due to the better transport links.The company building was largely constructed by the company members themselves. On 3 May 1974, Lothar Walther celebrated his 75th birthday and the company of the same name celebrated its 50th anniversary a year later. Lothar Walther himself was still active in the company, now supported by his two sons Klaus and Carl, who had taken over the management in the meantime.

At that time, the product range included barrels and insert barrels for rifles, pistols, and revolvers, as well as training barrels for shotguns, caliber adapters for sporting and hunting cartridges, training targets, and buffer cartridges for combination hunting guns and special tools. In subsequent years, crossbows for sport and recreational use were added to the product line. Many international successes were achieved with the "Match Tell" competition crossbow. The cheaper leisure models marketed under the names "Hobby Tell II" and "Hobby Tell II Sport" sold well.

In 1979, Lothar Walther celebrated his 80th birthday and could still be found at the factory. On 6 April 1983, the company founder passed away at the age of almost 84.

At the beginning of 1987, his son Klaus Walther took over the sole management of the company, supported by his sons Dr Frank Walther and Gerd Walther. In October 1994, the company moved into a comprehensive extension at Paul-Reusch-Strasse 34 in Königsbronn.

Within a year, modern offices and production facilities had been built there, as well as a technically better equipped warehouse for fast delivery to the trade. The leap into the USA and the improvement of market supply there followed in 1995, when a production and sales company was founded together with the long-standing representative in the USA.

The rented premises quickly became too small, and the US customers also wanted faster delivery times. The headquarters of Lothar Walther Precision Tool Inc. were therefore relocated to Cumming, Georgia, north of Atlanta. A modern production facility was built on a site measuring around 6,000 square metres.

Klaus Walther's sons, Dr Frank Walther and master craftsman Gerd Walther, have been running the company since 1997. Under their leadership, the company has been consistently modernized and strategically developed. Through continuous investment in state-of-the-art production facilities and innovative technologies, the company changed from a pure raw parts supplier to a system partner for drop-in barrels and precision components. On 10 January 2023, senior partner Klaus Walther, who continued to meet long-standing business partners at trade fairs well into his later years, passed away surrounded by his family at the age of 87.

In its centenary year, which the Königsbronn-based company celebrated with all employees in July with a company outing, the company boasts the world's largest range of barrel calibers: from 4 mm to 14.5x114 mm and from .17 Remington up to the big-game caliber .577, everything for hunting, sport, and self-defense.

The expertise gathered by the founder, modernised and supplemented, leads to key technologies for Lothar Walther barrels

Thanks to its mastery of both key technologies – button rifling and cold hammer forging – Lothar Walther can fulfil all customer requirements and guarantee precision at the highest level. With production, warehouse and office locations on two continents, state-of-the-art automation technology and highly qualified specialist staff, the company is in an excellent position to meet the constantly increasing demand for complete solutions in the field of gun technology. For this reason, an extensive expansion of production capacity in the USA is also planned: new machines, a significant increase in production space and a strengthening of the local team. Completely independent local production and the important "Made in USA" label are likely to prove to be the right strategic decision, especially in the current political situation and the threat of punitive tariffs on European steel products.

Today, the company supplies both traditional, artisanal gunsmiths and government agencies, proof houses, ammunition manufacturers, and leading companies in the defense sector. Barrels for AR15 rifles or for .50 caliber sniper rifles show the breadth of their product range, as does their confident presence at trade fairs for law enforcement and defense organizations, such as EnforceTac. The range of services extends from development and prototype construction to one-off production and small and large series. Whether it's a leisure gun, precision rifle or customised production for historical firearms, barrels and components bearing the Lothar Walther name can be found in virtually every type of firearm today, from air rifles for the Olympics to sniper rifles, and from black powder to nitrocellulose actions.

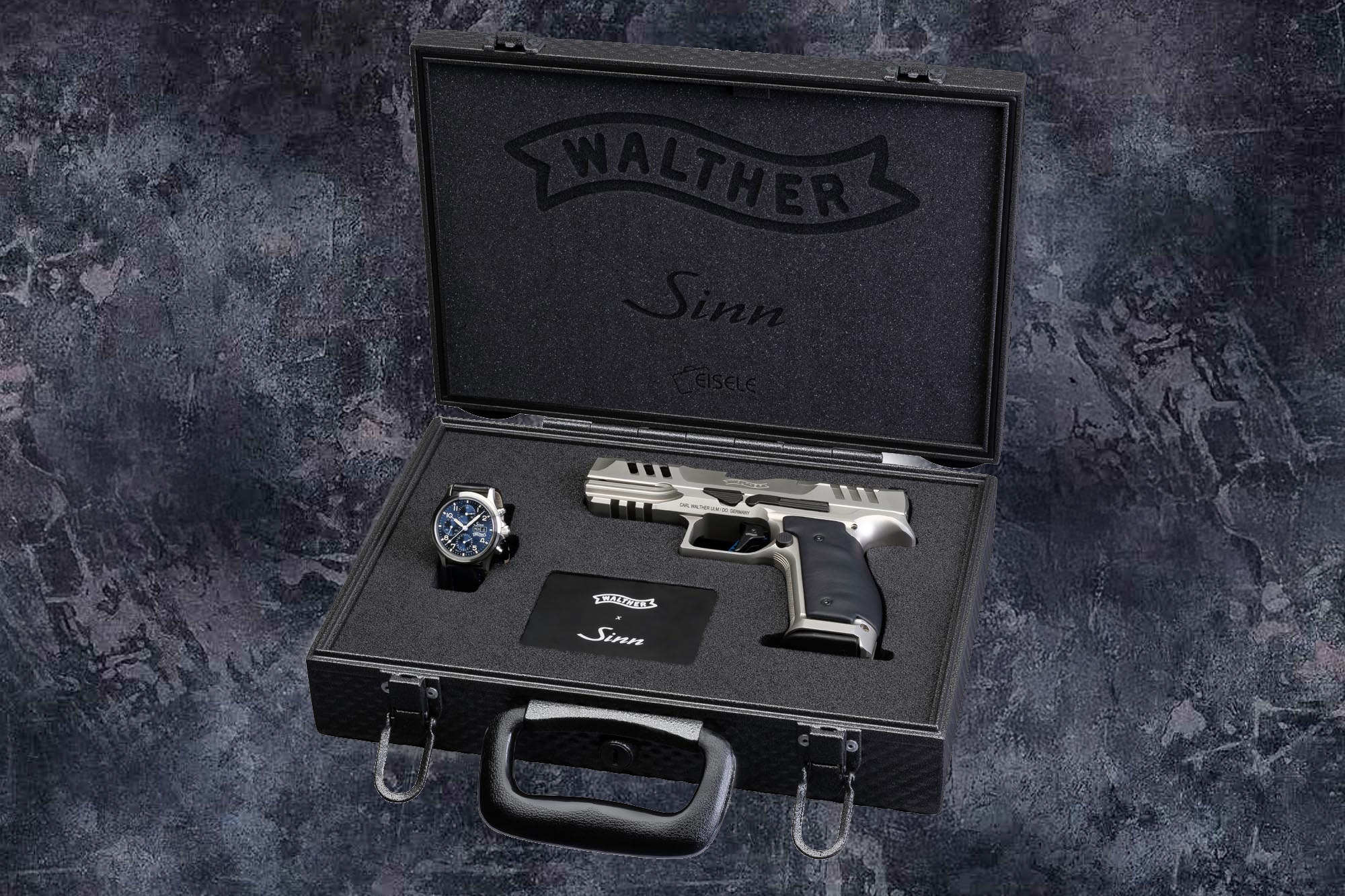

In addition to the firearms sector, the two Walther brothers are also opening up to other markets in order to ensure the stability of the company. Thanks to its exceptional machinery, with state-of-the-art technology for deep-hole drilling, honing, reaming and cold forming, the company also manufactures high-precision mechanical components for customers worldwide. In addition to existing partnerships in the optical, automotive and aerospace industries, medical technology in particular is increasingly becoming the focus of attention. Within the first century, the company name Lothar Walther developed into an independent and globally recognised brand, and the quasi-related company Carl Walther also advertises (like many other well-known manufacturers) with Lothar Walther barrels as a quality criterion.

The current presentation in modern media also fits in with the modern company line: the company website not only offers the complete product range, but also numerous videos on individual production steps and the company history – well worth watching!

Here you can find the company history of Lothar Walther on Youtube (video with English subtitles).