As one of the leading German hunting firearms manufacturers, Blaser has always endeavoured to improve its products for the customer. To achieve this goal, the company is constantly investing in new technologies. Blaser has now created a state-of-the-art surface technology centre at its home base in Isny in Allgäu. This is where the barrels of the R8 straight-pull bolt action rifle and all visible steel surfaces of the new Blaser FBX over-and-under shotgun are given their extremely resistant surface finish by applying the company's own DLC A+ coating as standard.

The DLC A+ coating is precisely matched to the physical and chemical properties of the materials used, resulting in a very high degree of hardness and excellent corrosion protection. The surfaces treated in this way remain protected against mechanical and weathering influences in the long term, which also reduces the maintenance effort for the hunter or, in the case of the FBX, also for the sport shooter.

Blaser DLC A+ coating – High-quality surface protection with diamond-like properties

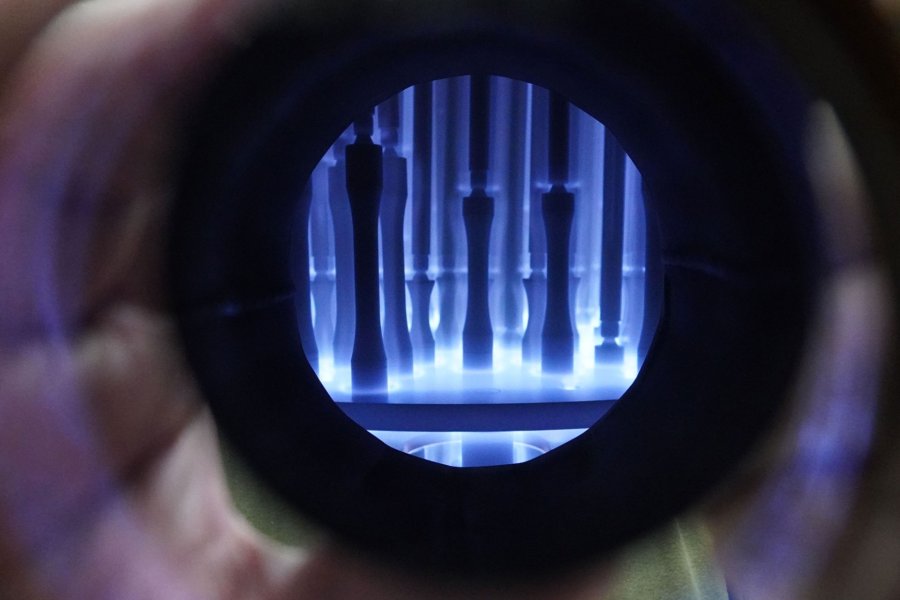

The DLC A+ coating from Blaser is based on the so-called Diamond-Like-Carbon technology. In a plasma-assisted chemical vapour deposition process, gaseous precursor molecules are activated in high-energy plasma and deposited on the components. In this way, an extremely thin layer of amorphous carbon is applied to the metallic surfaces. This layer, which is only a few nanometres thick, is around 18 times thinner than a human hair and has similar properties to diamonds – it is hard, smooth and wear- and corrosion-resistant. In order to achieve perfect results in terms of appearance, various steps must be carefully followed during the manufacturing of the parts which must also be perfectly cleaned again and again – especially before DLC coating. This is why, in addition to the coating systems, there is also a state-of-the-art cleaning system in the Blaser Surface Technology Centre.

The DLC process originally comes from industrial sectors in which particularly resistant and low-friction surfaces are required, for example in motorsport or toolmaking. In firearm manufacturing, this technology is primarily used to permanently protect components from mechanical and weather-related environmental influences and to maintain their mechanical function in the long term.

The DLC A+ coating offers a high level of protection against chemical influences such as acids, alkalis and salt water. At the same time, it reduces the friction of moving parts, which has a positive effect on durability. Different surface effects can be achieved through targeted pre-treatment. The barrels of the current R8 straight-pull rifles and the visible steel parts of the FBX over-and-under shotgun are blasted beforehand, giving the surface its silky matte, deep black and elegant appearance.

In addition to DLC coating, other coating processes based on gas deposition, such as PVD coating, can of course also be carried out in Blaser's new surface technology centre.

Further information on the DLC A+ coating can also be found on the Blaser website.