Article also available in other languages

Origins

It's difficult to find something grossly inadequate in the Tokarev TT33 semi-automatic pistol, which still today sees some military use in several Countries; and yet, the Soviet Union was already studying a possible replacement by 1939. The reason that led the Red Army officers − previously issued with Nagant revolvers − to ask for a replacement of the TT33 was that the shape of the Tokarev made it "difficult to operate the gun through the firing ports of a tank".

As the Second World War ravaged through Russia, these very same officers had to realize that a handgun was ill-useful for tank crews, and yet they probably refused to fully accept the concept, as a trial for a new service pistol was launched by 1945.

Submitted project should feature a 9x18mm chambering − a .32 ACP variant was previously included for Militsya (Police) issue, but the idea was later abandoned in favor of an unified caliber − but had to be shorter and lighter than the Tokarev pistol.

They also had to be more accurate, and their reliability had to be so improved over existing handguns of the era that basically any possible drawback had to be eliminated. And of course, their stopping power had to be the same as, or superior to, the Tokarev's.

The trial tests found the 9mm-caliber, Makarov-designed pistol prototype to be superior to all others; the weapon was thus officially adopted in 1951 as the Пистолет Макарова, "Makarov's Pistol".

The pistol

First and foremost, between all modern, steel-built, hammer-fired semi-automatic pistols, the Makarov PM is the one with the smallest number of parts − even less of the extremely simple and utterly reliable Beretta Model 34.

All components are built to last; they may be a little bit rude, but are robust and functional.

Nowadays, many of these parts would be made through sintering, metal injection molding, or other one-phase procedures − and indeed some are. The original Makarov components were instead obtained out of forged steel blanks, through complicated and expensive machining procedures.

Sintering procedures were already in use in Germany by the 1920s, but even after World War 2, Soviet manufacturing technology was not mature enough to implement it. Many smaller parts of PM were thus originally machined; later, they were produced by precision casting techniques rather than powder sintering.

Sure, workmanship costs were not a factor in the Soviet Union, but simpler manufacturing procedures were, as most of the Soviet gun plants workers back in the day had a very low degree of specialization; most of the previous-generations, more skilled workers had been replaced by women in the factories and sent to die in World War 2, and the training of a new generation of properly trained workers would take time.

The Makarov PM is shorter than the Tokarev TT33, given the smaller caliber, but the increased bore diameter allows the bullet to retain a good stopping power − even in comparaison with the 7,62x25mm-TT caliber − despite a lower muzzle velocity. The Makarov PM sports a shorter sight radius than the Tokarev pistol, and is normally just as accurate as a well-maintained TT; it is, however, much safer to operate, and also more durable, thanks to its blowback operation, which allows the use of a fixed barrel and eliminates the need for a barrel bushing.

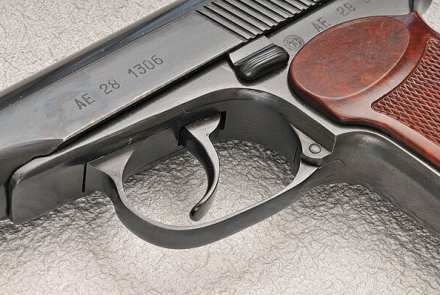

The Makarov PM pistol also sports a decocking safety switch, and feeds through a single-stack metal magazine, holding up to eight shots − the same capacity as the earlier Tokarev TT33.

Exception made for the single-piece grip overlay and the decocking safety lever, the pistol appears of no particular technical significance at a first glance; as usual, the genius behind it can be fully understood only upon a complete disassembly and a closer view of its components.

The Makarov PM field-strips through a Walther-type procedure: once the magazine is removed and the chamber is clear, the trigger guard is pulled downwards to free the slide from the frame; the slide itself can then be pulled rearwards, tilted upwards, and removed.

Although this field-stripping procedure led many analists, during the years, to think of the Makarov PM as nothing more, nothing less than a crude copy of the Walther PP/PPK pistol, that's not actually true at all. First and foremost of all, unlike the Walther, the Makarov can be field-stripped and reassembled without any tool whatsoever; the only external screw is the one found on the grip backstrap, holding the one-piece grip overlay in place, and if necessary can be unscrewed using a bullet case rim as a tool.

Said grip overlay is manufactured out of thermo-setting synthetic material, and its backstrap features a machined metal reinforcement plate − which, in turn, sports a pin that holds the screw in place, preventing it from coming loose with the recoil as the time goes by. The removal of the grip overlay will reveal the hammer spring and the magazine catch and release spring.

Both are held in place by a small metal sleeve, which in turn is kept secured to the frame by the backstrap screw.

Somebody once said that simplification in engineering comes when one single component performs multiple functions at the same time, while useless complications come when multiple components must perform the same function; well, if that's the case, what we have here is absolute genius applied to simplification at its best, since the two springs and the magazine catch are all obtained out of a bent metal band.

These aren't the only tasks performed by these springs, since the machined pad that operates the magazine release feacure is kept in place by another small bend in the lower portion of double spring itself.

The removal of the inner components of the pistol is just as simple: each one of them is kept in place by an integrated pin, so these need to be turned until these pins come out of their seats all by themselves; another smart, original and useful feature.

The striker is niftly conceived; it starts like a small metal cylinder, rounded on top, and is machine-cut until it reaches a pyramidal-like triangled shape. It's extremely stiff, with very little or no attrition with the walls of its seat in the slide; and it will never, ever break. It also sports no striker spring whatsoever, and is retained by the safety when it's engaged.

The safety catch − which also works as a decocker − can be extracted from its seat on the left side of the slide when the gun is disassembled.

When the gun is assembled, a protrudescence of the safety switch will hit against the frame to limit its movement to the two positions − safety engaged and disengaged − which can be limited with a click. The trick is done by a simple harmonic steel wire piece, which engages a punching hole that retains it.

In order to prevent ejected cases to recoil along with the retreating slide as the gun cycles, up to a point when it could interfere with the fresh round being chambered, its bottom almost totally rests against the breechblock's face; a small milled hollow prevents metal parts to touch the primer when the round is being chambered. During the reloading cycle, the fresh cartridge pushes the light striker rearwards.

The barrel is machined out of a three-diameter metal tube − the feeding ramp is obtained out of the higher-diameter portion − and is lodged into a sleeve, which is by itself pinned to the frame. Said sleeve also sports a seat that holds the trigger in place through its integrated retention pin. The trigger itself can be removed once its guard has been pulled downwards.

The most interesting mechanical solution to be found in the Makarov PM pistol is the trigger bar, which of course controls both the single-action and double-action operation.

Generally speaking, these parts sport a prominent U-shape, and tends to bend when the trigger is pulled, thus causing a variation in contact points.

The Makarov bar design solves this inconvenient by featuring a short cylindric segment in its front portion, which is oriented rearwards rather than to a 90-degrees position.

Said segment engages the tighter portion of a conic hole located in the trigger, so that the traction from the trigger itself always comes from the same point − the one adjacent to the longer side of the bar; as there is no significant force being applied to the front portion of the bar, it will not bend.

The rear portion of the trigger bar engages a complex, extremely short lever, which rotates in an almost vertical position to activate the double action.

This lever comes with two pawls: the lower one will cock the hammer, while the higher one will intervene once the hammer is fully cocked, engaging the sear pin to release it; that's thus a positive hammer release double action.

What is peculiar in this system is that the translating movement of the lever appears to find no comparaison with any other working system on any other existing firearm.

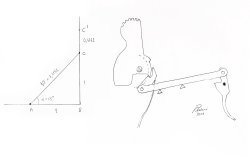

This drawing by the Italian technician Roberto Palamà explains the advantage of such a design: the horizontal (a->b) sliding of the trigger bar causes a vertical movement of the hammer release lever (a->b – (√2-1)).

It is not a linear progression; as a matter of fact it seems related to the alpha angle cotangent.

The drawing is indeed simplified, as the hammer cocking movement is not rectilinear but follows a curve as the hammer itself pivots around a pin; and yet, this simplification helps to understand.

This solution provides a very clean double-action trigger pull, much akin to the effect obtained by the interposition of the hammer and the main spring in an external-hammers shotgun.

There is some space between the trigger bar and the double action lever − and that's because disconnection takes place sideways on the Makarov PM pistol. The lever itself is moved by the recoiling slide, which blocks the sear; as the slide returns to its locked position, the sear is released and the gun is ready to fire again. Sideways disconnection, the trigger group occupies a mere portion of the entire space that'd be theoretically available; the hammer pawl only takes up to ¾ of the section of the hammer itself.

After over half a Century of well respected service, the Makarov PM pistol has not yet been officially declared obsolete by the Russian Armed Forces or the Russian Government: the 9x19mm-caliber PYa "Yaryigin" pistol is being issued as a complement, and will eventually replace it, but the Makarov PM is still issued in enormous numbers by the Russian Armed Forces and Law Enforcement agencies. Reason is quite simple: there's too many Makarovs still in serviceable condition in Russian arsenals.

This is typical for Soviet and Russian war machine: old system are not declared obsolete despite adoption of newer systems. That's the reason why the Makarov pistol is also still in use with the militaries and Police forces of several former Warsaw Pact and other "Communist Bloc" Countries.

Commercial variants are also manufactured in China, Russia and Bulgaria, and sold mainly on the civilian market, where the Makarov is highly appreciated as a concealed carry pistol.

The only noticeable drawback of the Makarov pistol design is the peculiar 9x18mm-PM caliber, generally regarded as lacking stopping power by modern canons, and difficult to reload; but on the other hand, employing a higher caliber on a pistol with such a design would make it difficult to handle (and owners of the Campo-Giro and other Spanish-made pistols know it very well).

If you load your own ammunition, keep in mind that the 9x18mm-PM caliber ball sports a real diameter of 9,2mm to 9,3mm; standard 9mm Luger brass can be trimmed down to obtain a proper 9x18mm-PM case, but in this case, all brass should be carefully weighed before reloading.